Manufacturers today operate under constant pressure volatile demand, supply-chain disruptions, labor shortages, equipment failures, and fragmented systems that slow decision-making. Odoo for Manufacturing was designed to solve these problems with one connected ERP that unifies planning, production, inventory, quality, costing, and maintenance.

This blog explores how Odoo supports modern manufacturing, what features matter most on the shop floor, how it compares to other manufacturing ERPs, and why many factories choose Odoo as their core system.

Why Odoo Fits Today’s Manufacturing Challenges

Manufacturing rarely happens inside one system. Many factories still rely on separate tools for planning, inventory, quality checks, maintenance tracking, and procurement. This slows teams down and creates information gaps.

Odoo brings everything together:

Manufacturing (MRP)

Shop-floor execution (MES)

Inventory & WMS

Quality & PLM

Costing & Finance

Procurement

IoT & Machine Integrations

Because all modules run in a unified platform, factories get real-time visibility across their operations. Whether you manage discrete production, process manufacturing, or multi-plant environments, Odoo adapts smoothly.

Key Capabilities of Odoo Manufacturing

Real-Time Production Visibility

Material Planning (MRP) That Works

Quality Control at Every Stage

Traceability for Compliance

Accurate Costing & Profitability

IoT & Shop-Floor Data

Advanced Features Manufacturers Rely On

Multi-Level BOM & Engineering

Odoo handles multi-level BOMs, variants, by-products, subcontracting, and engineering change orders. PLM tools help manage documentation and version control.

Work Centers & OEE Tracking

Teams monitor downtime, cycle times, availability, and performance to improve productivity and capacity planning.

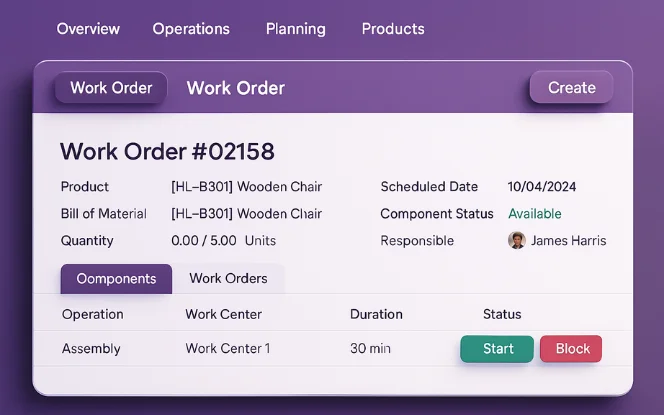

MES for Floor-Level Execution

Warehouse Automation (WMS)

Predictive & Preventive Maintenance

Finance Integration

How Odoo Supports the Manufacturing Lifecycle

1. Planning

2. Production

3. Inventory

4. Quality

5. Procurement

6. Costing

7. Maintenance

This end-to-end flow is what makes Odoo valuable for fast-growing factories.

What SDLC Corp Brings to Odoo Manufacturing Implementations

Odoo’s power increases dramatically when implemented with precision. SDLC Corp ensures the ERP reflects real manufacturing conditions and supports long-term stability.

We typically:

- Map production flows from sales order to shipment

- Design accurate routing, work centers, BOMs, and planning rules

- Build operator-focused MES screens for clarity and speed

- Configure warehouses according to racks, zones, and movement patterns

- Implement quality rules, traceability, and CAPA

- Set up reliable costing and analytics dashboards

- Integrate machines, scanners, IoT devices, and external systems

Manufacturers often reach a point where they need a consistent Odoo engineering partner. At that point, they choose to hire Odoo developer from SDLC Corp to ensure stable architecture, continuous improvements, and long-term support.

Where Odoo Stands Compared to Other ERP Systems

Manufacturers often evaluate Odoo alongside systems like SAP Business One, Acumatica, and Epicor. Each has strengths, but Odoo stands out in a few key areas:

Odoo vs. SAP Business One

SAP is strong but expensive and less flexible

Odoo offers open customization and faster deployment

Odoo vs. Acumatica

Acumatica suits mid-sized manufacturers

Odoo provides broader modular coverage and lower long-term costs

Odoo vs. Epicor Kinetic

Epicor is deep in manufacturing

Odoo is easier to adapt, integrate, and extend

For factories wanting modern workflows without overspending on licensing, Odoo becomes the preferred choice.

Why Manufacturers Choose SDLC Corp

Factories trust SDLC Corp because we build systems tailored to real production environments—not theory. We understand scheduling constraints, quality requirements, supply chain behavior, and costing precision.

The result is an Odoo setup that:

Boosts productivity

Reduces operational errors

Improves costing accuracy

Supports growth and scalability

Final Thoughts

Odoo for Manufacturing gives factories a connected system that improves planning, execution, quality, and costing. When implemented correctly, it becomes the backbone of a modern factory.

SDLC Corp helps manufacturers build reliable, scalable Odoo ecosystems designed around real shop-floor needs. If you’re exploring digital transformation or improving operational efficiency, Odoo is a strong foundation—and the right implementation partner makes all the difference.

Also Read :

1) Odoo manufacturing implementation

2) Integrating IoT with Odoo for Manufacturing

FAQ's

What Is Odoo Manufacturing (MRP) And How Does It Help Factories?

Odoo Manufacturing (MRP) is an all-in-one ERP system designed to provide factories with full visibility, control, and agility across the production lifecycle. It helps manage raw materials, optimize shop floor operations, schedule work orders, track inventory in real time, and handle quality and maintenance processes, all from a centralized platform.

What Are The Main Challenges Faced By Modern Manufacturers That Odoo Addresses?

Manufacturers face challenges like managing complex Bill of Materials (BoM), scheduling work orders across multiple centers, tracking inventory and production costs in real time, conducting quality checks, and preventive maintenance. Odoo integrates all these functions to improve efficiency, traceability, and profitability.

How Does Odoo Simplify Bill Of Materials (BoM) Management?

Odoo supports multi-level BoMs with instructions and documentation attachments such as PDFs and drawings. It maintains costing and version control, providing full traceability and structured management of manufacturing components.

What Scheduling And Production Planning Features Does Odoo Offer?

Odoo allows manufacturers to define routing instructions, assign steps to specific work centers, and sequence operations to mirror actual production flow. It includes a drag-and-drop Gantt chart to visualize, schedule, and adjust production timelines dynamically

How Is Inventory Managed And Tracked In Odoo Manufacturing?

Inventory is integrated with barcode scanning and traceability features, offering real-time stock visibility across locations. Odoo supports serial and lot tracking and seamlessly integrates inventory with warehouse operations, procurement, and production workflows.

What Quality Control Capabilities Are Built Into Odoo Manufacturing?

Odoo includes automated quality checkpoints linked to production orders, inspection checklists, and the ability to attach files or photos as evidence. This ensures product compliance and helps maintain high standards throughout production.

How Does Odoo Support Preventive Maintenance In Manufacturing?

Odoo allows scheduling of preventive and corrective maintenance tasks linked to specific machines or work centers. This helps reduce downtime, increase equipment reliability, and maintain historical maintenance logs.

Can Odoo Manufacturing Integrate AI Technologies?

Yes, while Odoo is not an AI engine by itself, it can be enhanced with AI modules for demand forecasting, predictive maintenance, quality control automation, and smart inventory management, helping manufacturers optimize operations with intelligent insights.

Is Odoo Suitable For Manufacturers Of All Sizes And Industries?

Odoo is scalable and adaptable, making it suitable for small workshops, mid-sized operations, and large enterprises across various industries such as furniture, electronics, food, metalwork, textiles, and chemicals.

What Makes Odoo Manufacturing Different From Other ERP Systems?

Odoo is open-source and highly customizable, offering complete freedom to add new workflows, modules, and automations. It provides seamless integration with all business departments like sales, purchasing, accounting, and HR, eliminating data silos and enabling smarter, more efficient manufacturing.