Introduction

Odoo for Food and Beverage Industry operations demand accuracy, traceability, and regulatory discipline across production, inventory, and distribution. Therefore, food businesses require ERP systems that support perishable goods and multi-stage supply chains without adding complexity.

Odoo provides a unified platform that connects manufacturing, inventory, quality, and finance in one system. As a result, teams work with consistent data and structured workflows across daily operations.

To understand how this structure works in practice, explore our Odoo ERP implementation services covering planning, configuration, and governance for food businesses.

Industry-Specific Operational Complexity

Food and beverage operations face constraints that differ from most industries. Products expire quickly. Regulations demand detailed records. Meanwhile, supply chains involve many suppliers and locations. Therefore, even small errors can lead to waste or compliance risk.

Key challenges include:

- Batch-based production with variable yields

- Shelf-life limits that affect inventory decisions

- Audit requirements that demand historical accuracy

- Distribution dependencies such as cold-chain handling

Moreover, disconnected systems weaken data reliability. Teams often rely on spreadsheets, which increases errors and slows response times. As a result, decisions depend on partial information.

Odoo centralizes operational data so every transaction updates related workflows automatically. Inventory reflects production activity. Quality records link to batches. Finance stays aligned.

For deeper alignment between systems and operations, refer to our ERP consulting approach for regulated industries.

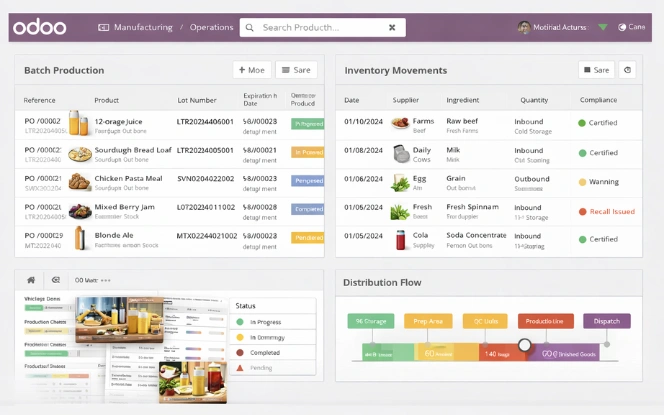

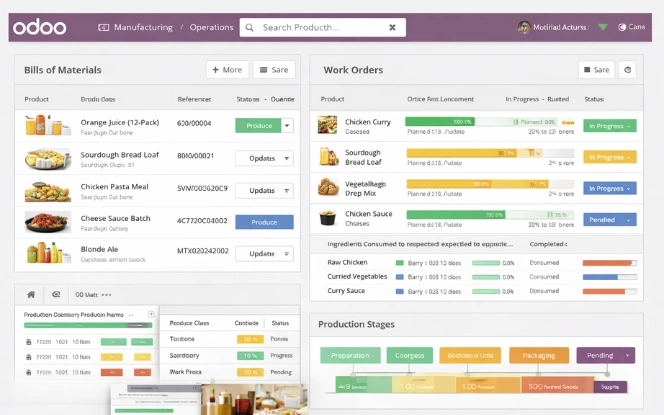

Production Management and Manufacturing Control

Food manufacturing requires repeatable processes and controlled variation. Recipes must remain consistent. At the same time, teams need flexibility to manage raw material differences.

Odoo supports structured production through:

- Bills of materials with version control

- Defined production routes and work centers

- Real-time tracking of work orders and outputs

Quality checks integrate directly into production flows. Deviations trigger corrective actions early, which reduces waste and rework. Over time, production history reveals yield trends and downtime patterns.

Organizations using Odoo ERP for Food Manufacturing gain better control without slowing execution. Managers rely on data instead of assumptions, which improves planning accuracy.

To see how production setups are defined, review our Odoo manufacturing module configuration guide focused on recipes, routing, and checkpoints.

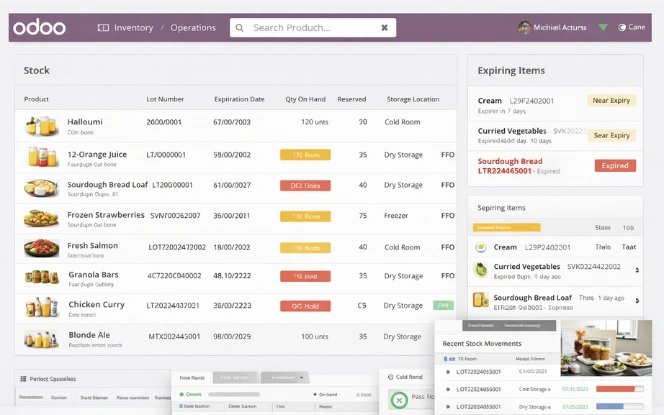

Inventory Accuracy and Shelf-Life Control

Inventory errors directly impact profitability in food businesses. Overstock leads to spoilage. Understock disrupts service levels. Therefore, systems must track quantity, location, and expiration together.

Odoo provides:

- Real-time stock visibility across warehouses

- FIFO and FEFO picking rules

- Automated replenishment triggers

Inventory movements also update accounting records instantly. This integration improves cost visibility and margin tracking. Finance teams work with accurate data without manual adjustments.

For organizations managing perishable goods, Odoo Inventory Management for Food Businesses improves accuracy while reducing waste. Inventory decisions rely on current data rather than estimates.

For practical methods to reduce spoilage, see our inventory optimization framework for perishable goods.

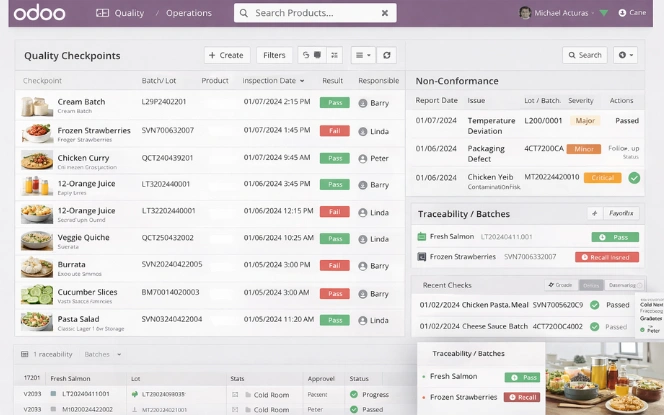

Quality Management and Compliance Readiness

Food safety depends on traceability and documentation. Regulators expect clear, verifiable records. Therefore, quality management must integrate with operations. Odoo embeds quality checks at key stages, including receiving, production, and delivery. Non-conformances trigger corrective actions, and documentation remains audit-ready.

Quality workflows include:

- Linked batch and supplier records

- Inspection checkpoints

- Corrective action tracking

Because quality data connects with inventory and production, recalls become faster and more controlled. Teams isolate affected products quickly. By applying Odoo Traceability and Quality Control, businesses meet compliance requirements without slowing operations

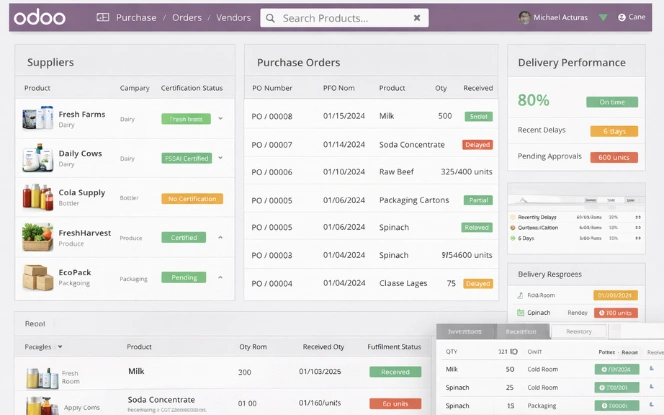

Procurement and Supplier Accountability

Supplier performance directly affects product quality and delivery reliability. Therefore, procurement decisions must rely on evidence rather than memory.

Odoo centralizes supplier profiles, certifications, and transaction history. Purchase orders connect to receipts and invoices, which improves transparency.

Procurement teams benefit from:

- Supplier performance tracking

- Certification management

- Price and delivery history

Organizations using Odoo Food and Beverage ERP improve sourcing discipline while retaining flexibility.

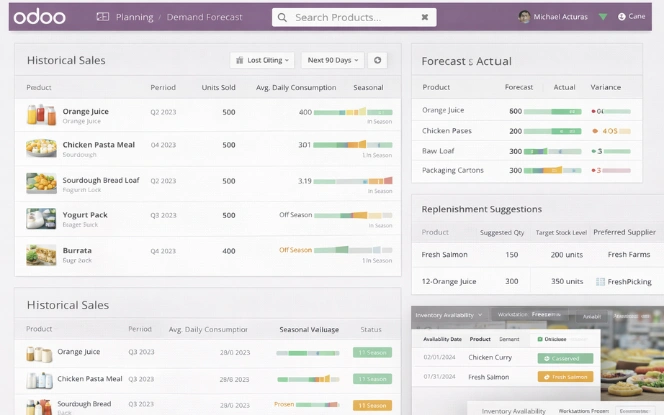

Demand Planning and Forecast Accuracy

Demand in food markets fluctuates due to seasonality, promotions, and regional preferences. Static forecasts often fail under these conditions. Odoo supports demand planning through historical sales data and trend analysis. Planners review performance across periods and locations, then adjust forecasts based on real conditions.

Businesses using Odoo ERP for Restaurants and Cafes benefit from improved stock availability and reduced waste. To align forecasts with operations, explore our On Demand Food Delivery App Development Company

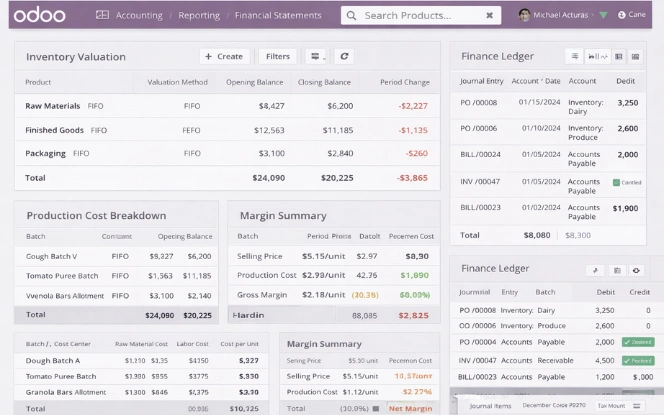

Financial Integration and Cost Visibility

Food businesses operate on thin margins. Ingredient price changes affect profitability quickly. Therefore, financial systems must stay aligned with operations.

Odoo links accounting with inventory, production, and procurement. Costs are allocated automatically based on consumption and labor. Margin reports reflect actual performance.

Organizations using Odoo ERP for Food Manufacturing gain financial clarity without increasing administrative effort.

Conclusion

Odoo provides structured support for food and beverage operations that demand accuracy, compliance, and scalability. By integrating production, inventory, quality, and finance, businesses gain operational clarity and consistency. When organizations apply Odoo for Food and Beverage Industry practices with discipline, they reduce waste, improve traceability, and strengthen governance.

For expert guidance on implementation and optimization, Contact us SDLC Corp.

FAQs

What Is Odoo Used For In The Food And Beverage Industry?

Odoo helps food and beverage businesses manage production, inventory, quality checks, and compliance using one centralized ERP system with real-time data control.

How Does Odoo Support Food Manufacturing Operations?

Odoo ERP for Food Manufacturing supports recipe management, batch production, inventory consumption tracking, and quality checkpoints across the full manufacturing workflow.

Can Odoo Manage Inventory For Perishable Food Products?

Yes, Odoo Inventory Management for Food Businesses supports lot tracking, expiration dates, FIFO and FEFO rules, and real-time stock visibility to reduce spoilage.

Is Odoo Suitable For Restaurants And Cafes?

Odoo ERP for Restaurants and Cafes supports purchasing, inventory control, sales integration, and financial tracking while maintaining consistency across multiple locations.

How Does Odoo Handle Traceability And Quality Control?

Odoo Traceability and Quality Control links suppliers, batches, inspections, and corrective actions, helping businesses meet food safety regulations and audit requirements.