Introduction

Global retail and e-commerce supply chains are becoming more complex with rising customer expectations, shorter delivery cycles, and fluctuating market demands. Companies are under constant pressure to cut costs, improve efficiency, and maintain accuracy across operations. Many organizations are now exploring advanced supply chain management software solutions to address these challenges and stay competitive.

In this environment, AI in supply chain is emerging as a game-changer. By converting raw data into actionable insights, it enables smarter demand forecasting, precise inventory optimization, and seamless decision-making.

What is AI in Supply Chain Management?

AI in supply chain management refers to the use of artificial intelligence, machine learning, and predictive analytics to improve operations. Unlike traditional supply chain models, these systems learn from historical and real-time data. This enables:

Accurate Demand Planning – AI uses historical sales, seasonal patterns, and external data to predict demand, reducing stockouts and overstocking.

Optimized Production Schedules – Aligns manufacturing with demand forecasts, minimizing downtime and ensuring efficient use of resources.

Smarter Supplier Selection – Evaluates suppliers on cost, quality, and delivery performance to strengthen reliability and reduce risks.

Faster Logistics Planning – Optimizes delivery routes, lowers transportation costs, and ensures quicker, disruption-free shipments.

Read more – Generative AI for Supply Chain

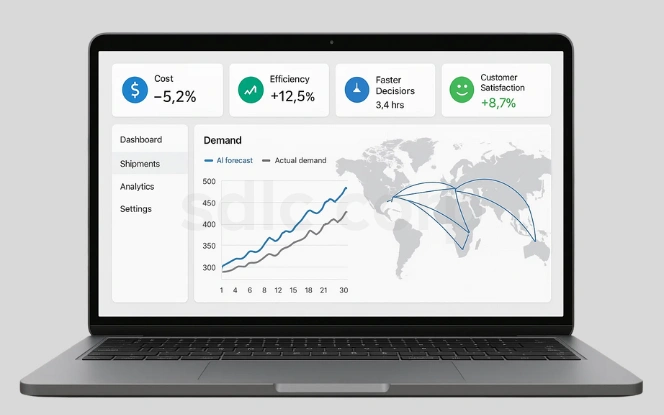

Benefits of AI in Supply Chain

Companies adopting intelligent supply chain models are seeing measurable improvements across operations. Key benefits include:

- Cost reduction: Smarter inventory controls reduce overstocking and stockouts.

- Efficiency gains: Automation speeds up order routing and invoice processing.

- Faster decision-making: Predictive analytics highlight risks and recommend proactive actions.

- Customer satisfaction: Accurate planning ensures timely deliveries.

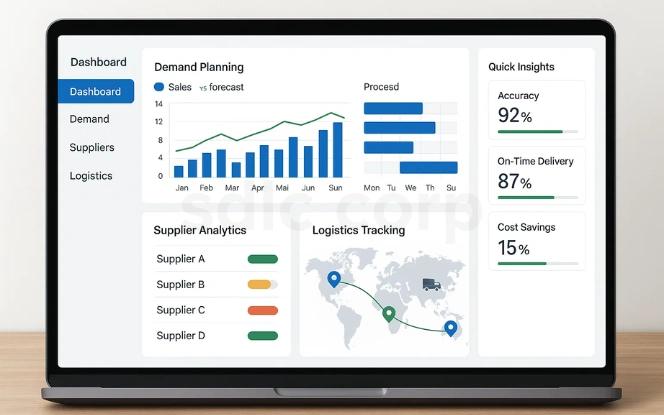

Key Applications of AI

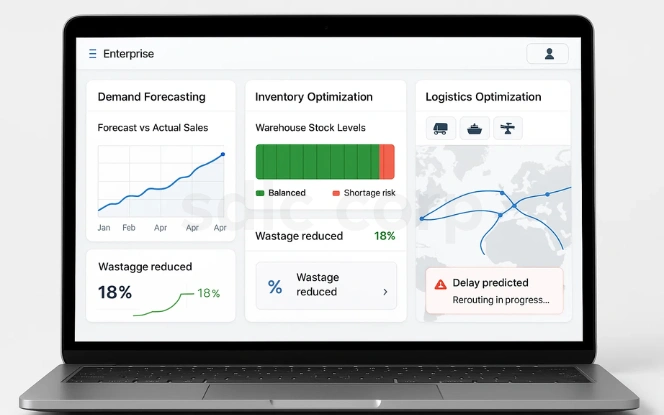

1. AI Demand Forecasting

One of the most impactful areas is AI demand forecasting. By analyzing historical sales, seasonality, and market data, it predicts demand patterns with high accuracy. For e-commerce, this ensures balanced inventory levels during events like Black Friday or festive seasons.

2. AI Inventory Optimization

With AI inventory optimization, businesses maintain the right stock levels, reducing waste and avoiding shortages. For example, AI-powered inventory optimization for restaurants helps dining chains cut food spoilage while meeting unpredictable demand.

3. AI Logistics Optimization

AI logistics optimization minimizes costs by planning efficient routes, predicting delays, and improving last-mile delivery. Combined with IoT sensors, it provides real-time shipment visibility.

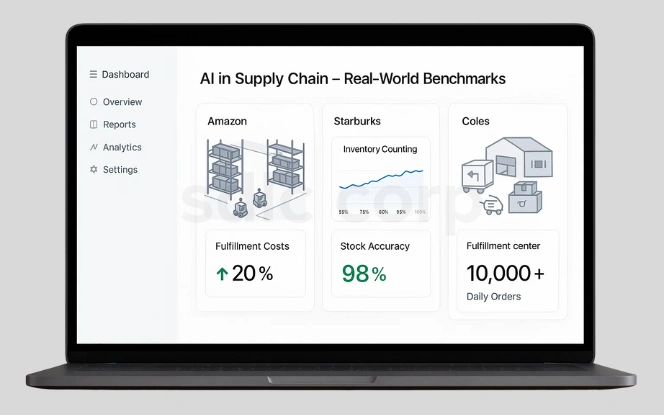

Real-World Examples of AI in Supply Chain

Several global brands are setting benchmarks:

- Amazon uses robots and predictive analytics to cut fulfillment costs.

- Starbucks deployed AI-based inventory counting to improve stock accuracy.

- Coles (Australia) operates AI-driven fulfillment centers to process thousands of online orders daily.

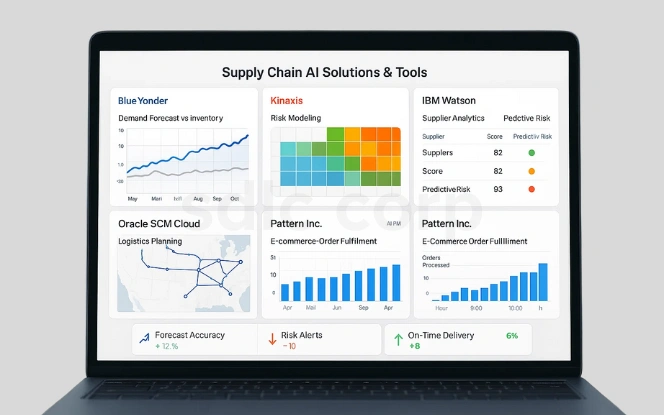

Supply Chain AI Solutions & Tools

Businesses exploring digital transformation can choose from various supply chain AI solutions that improve planning, forecasting, and logistics. Leading providers include:

- Blue Yonder – Offers AI-driven planning and demand forecasting for better inventory visibility.

- Kinaxis – Provides real-time risk modeling and supply planning.

- IBM Sterling / Watson – Uses predictive analytics and supplier management tools to strengthen resilience.

- Oracle SCM Cloud – Delivers smart operations and logistics planning with cloud-based AI.

- Pattern Inc. – Focuses on e-commerce with AI-powered forecasting and fulfillment optimization.

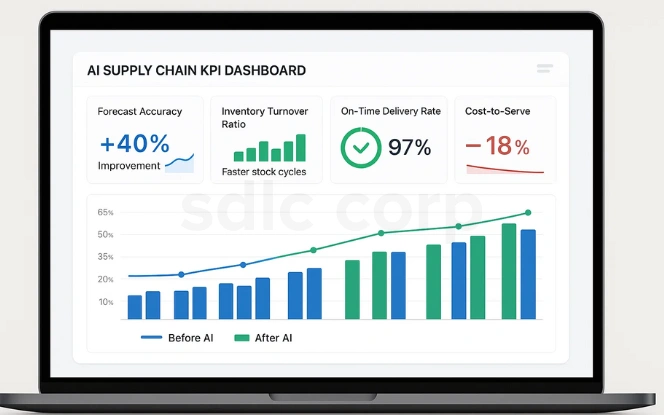

Key Metrics and KPIs Optimized by AI

AI-driven supply chains deliver measurable outcomes across critical KPIs:

- Forecast Accuracy (FA): Reduces demand error rates by up to 40%.

- Inventory Turnover Ratio: Accelerates stock movement.

- On-Time Delivery Rate: Improves through predictive logistics.

- Cost-to-Serve: Cuts costs with automation and reduced waste.

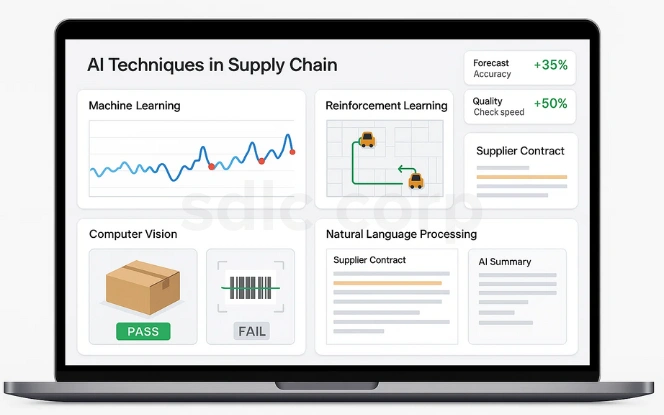

AI Techniques in Supply Chain

Different branches of AI strengthen supply chains in specific areas:

- Machine Learning (ML): Improves demand prediction and anomaly detection.

- Reinforcement Learning (RL): Powers warehouse robotics and real-time decisions.

- Computer Vision (CV): Automates quality checks and barcode scanning.

- Natural Language Processing (NLP): Simplifies contract analysis and supplier communications.

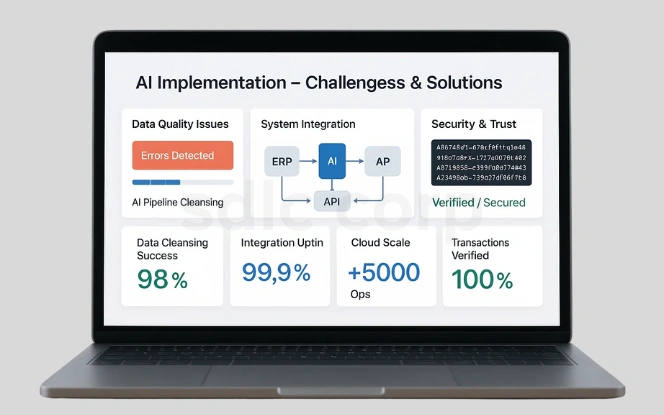

Implementation Challenges & Solutions

Adopting AI is not without challenges:

- Data Quality Issues: Resolved through cleansing and normalization pipelines.

- System Integration: APIs connect AI modules with ERP and SCM systems.

- Scalability: Cloud AI (AWS, Azure, GCP) ensures global scale.

- Security & Trust: Blockchain integration enhances transparency and traceability.

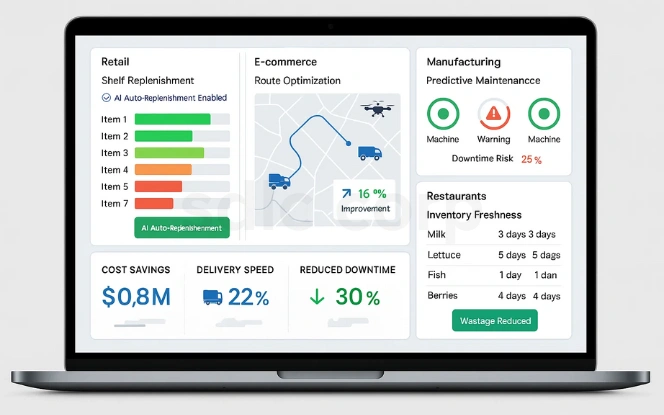

Industry-Specific AI Use Cases

AI in the supply chain is not limited to one sector. Different industries apply it in unique ways to improve efficiency, cut costs, and deliver better customer experiences. Here are some domain-specific applications:

- Retail: Real-time replenishment using AI + IoT ensures shelves stay stocked while minimizing excess inventory.

- E-commerce: Delivery slot optimization with AI-driven route planning improves last-mile delivery speed and reduces delays.

- Manufacturing: Predictive maintenance with IoT sensors helps reduce downtime by identifying equipment failures before they occur.

- Restaurants: Perishable inventory optimization with AI models minimizes food waste and ensures fresh stock availability.

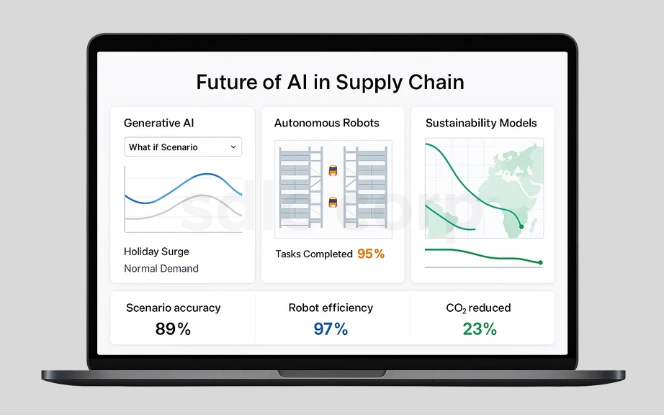

Future of AI in Supply Chain

Generative AI is giving fashion companies more than just speed and efficiency it’s helping them reinvent how they work and connect with customers. Here are some of the biggest benefits:

The future will see deeper integration of advanced technologies:

- Generative AI for scenario planning – Simulates “what-if” scenarios by analyzing datasets such as sales, logistics, and weather.

- Autonomous robots in warehouses – Using computer vision and reinforcement learning, robots will manage picking and auditing with minimal input.

- Sustainability-focused AI models – Algorithms will track emissions, optimize routes, and improve recycling in circular supply chains.

Conclusion

The adoption of AI in supply chains is no longer optional it is now a necessity for retail and e-commerce growth. From AI demand forecasting to inventory optimization and logistics improvements, AI enables agility, resilience, and faster decision-making.

To fully leverage these benefits, companies should explore proven platforms and consider hiring AI developers who can build customized solutions. Preparing today with AI-driven strategies ensures smarter, more efficient, and future-ready supply chain operations.

Related Blogs You Should Explore:

FAQ's

How Is Ai Applied In Supply Chain Operations?

AI supports areas like demand forecasting, inventory management, route optimization, and supplier risk assessment. It uses predictive analytics to improve efficiency and accuracy.

What Are The Key Benefits Of Adopting Ai Technologies?

Companies see reduced costs, better forecasting, streamlined logistics, and improved customer satisfaction when adopting intelligent supply chain solutions.

Which Industries Benefit The Most From Ai-driven Supply Chains?

Retail, e-commerce, manufacturing, and restaurants all benefit. Examples include predictive maintenance in factories and perishable stock optimization in food businesses.

What Challenges Occur When Implementing Ai Solutions?

Businesses often face issues with data quality, integrating AI into legacy ERP systems, ensuring scalability, and maintaining data security.

What Is Ai Demand Forecasting?

It uses machine learning models to predict future product demand by analyzing historical sales, seasonality, and market conditions. This reduces stockouts and overstocking.