Introduction

The automotive industry operates in a fast-changing, highly competitive environment where managing production, inventory, suppliers, quality, and customer expectations is critical. Odoo for Automotive unifies these processes into a single ERP platform, improving visibility, workflow efficiency, and decision-making supported by a trusted Odoo Development Company for scalable implementation.

1. Why Odoo for Automotive Is Essential for Modern Businesses

The automotive industry relies on tightly connected processes across production, inventory, supply chain, and sales. However, managing these processes without an ERP system often leads to inefficiencies and data gaps. Therefore, adopting an ERP solution has become essential for automotive businesses aiming for sustainable growth.

Increasing Operational Complexity

As automotive companies expand, their daily operations become more complex and harder to manage.

Key challenges include:

Managing multiple suppliers and vendors

Coordinating production across different facilities

Tracking inventory across warehouses and locations

Aligning sales, service, and finance teams

Without a centralized system, these challenges often result in delays and errors. An ERP system like Odoo connects all departments, ensuring smoother coordination and improved accuracy.

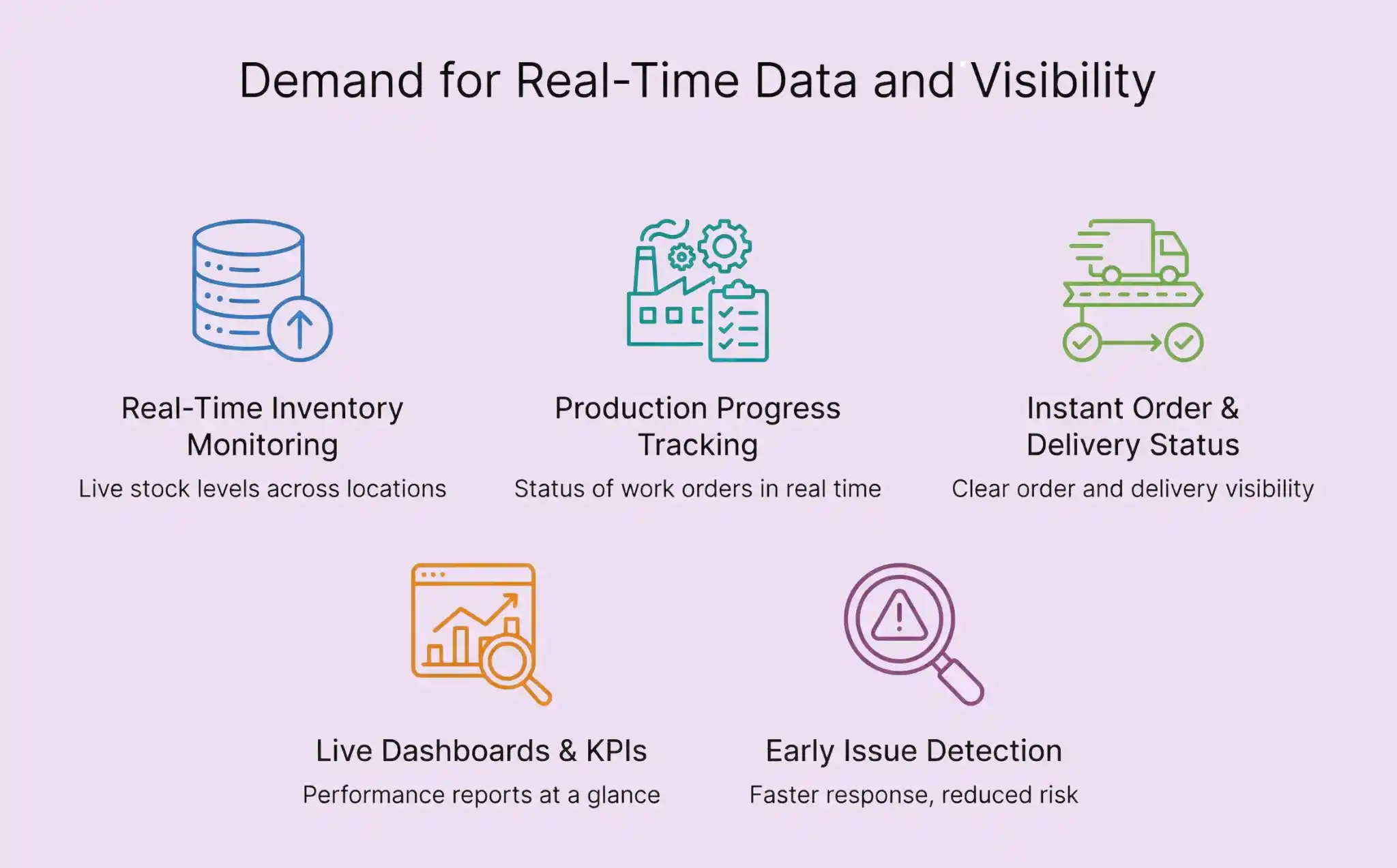

Demand for Real-Time Data and Visibility

Automotive businesses need instant access to operational data to make timely decisions.

With an ERP system, companies can:

Monitor inventory levels in real time

Track production progress across work orders

View order status and delivery timelines instantly

Access live dashboards and performance reports

As a result, managers can identify issues early and respond quickly, reducing operational risks.

Rising Customer Expectations

Customer expectations in the automotive industry continue to rise. Buyers demand faster delivery, better communication, and consistent product quality.

ERP systems help meet these demands by:

Automating order processing

Reducing errors in production and fulfillment

Improving coordination between sales and service teams

Ensuring on-time deliveries

Consequently, businesses can improve customer satisfaction while maintaining operational efficiency.

Need for Cost Control and Operational Efficiency

Automotive operations involve high costs related to materials, labor, and logistics. Without proper tracking, these costs can impact profitability.

An ERP system supports cost control by:

Reducing manual processes and human errors

Optimizing inventory levels to avoid overstocking

Improving production planning and resource usage

Providing accurate financial tracking and reporting

Therefore, automotive companies gain better control over expenses and improve overall efficiency.

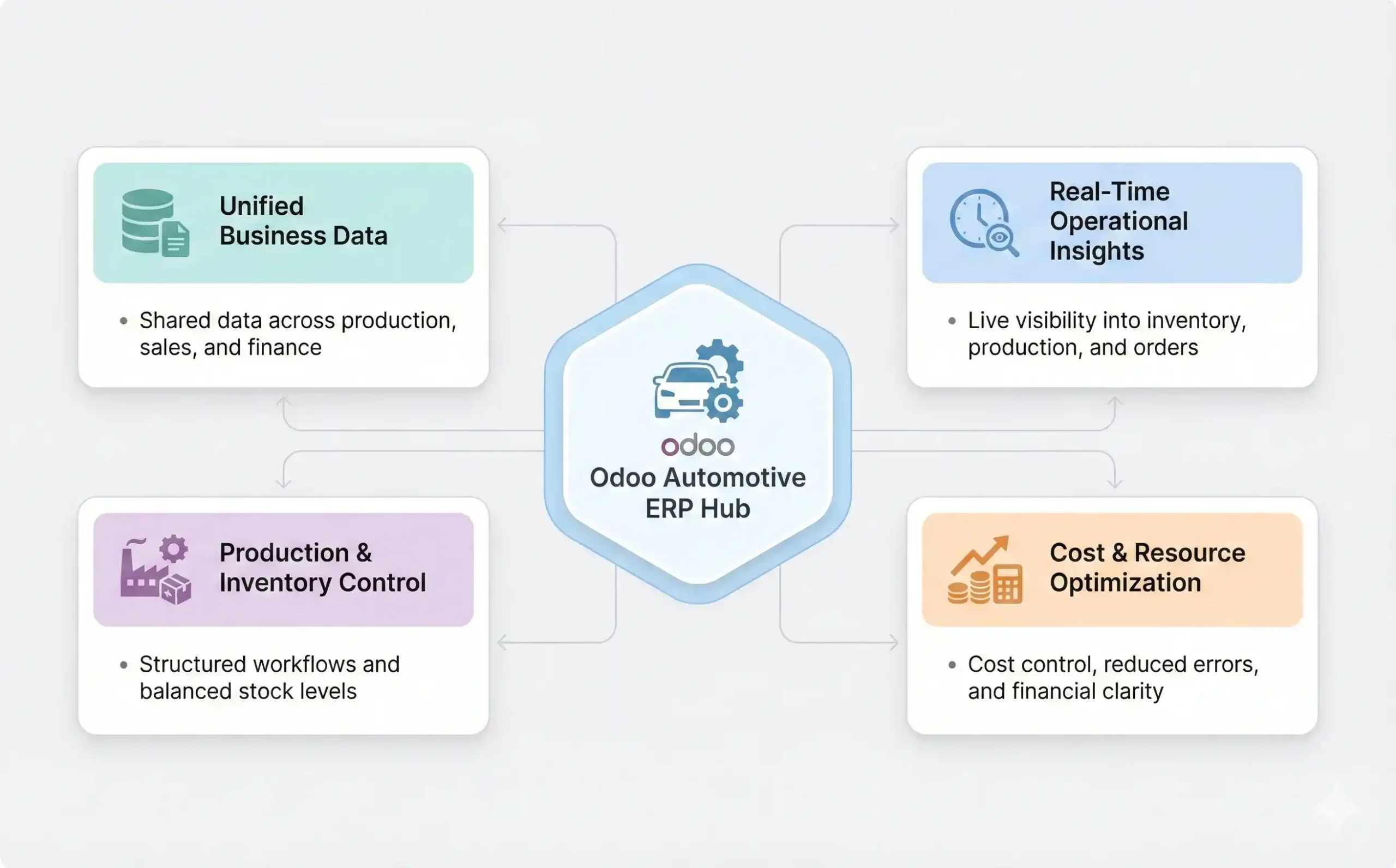

2. How Works Odoo for Automotive ERP

Odoo for Automotive businesses delivers practical benefits that help manage complex operations with ease. By using a single ERP platform, automotive companies can streamline workflows, reduce errors, and improve overall efficiency. As a result, teams can focus more on growth and less on manual tasks.

Read Also : How Odoo ERP Revolutionizes Automotive Manufacturing

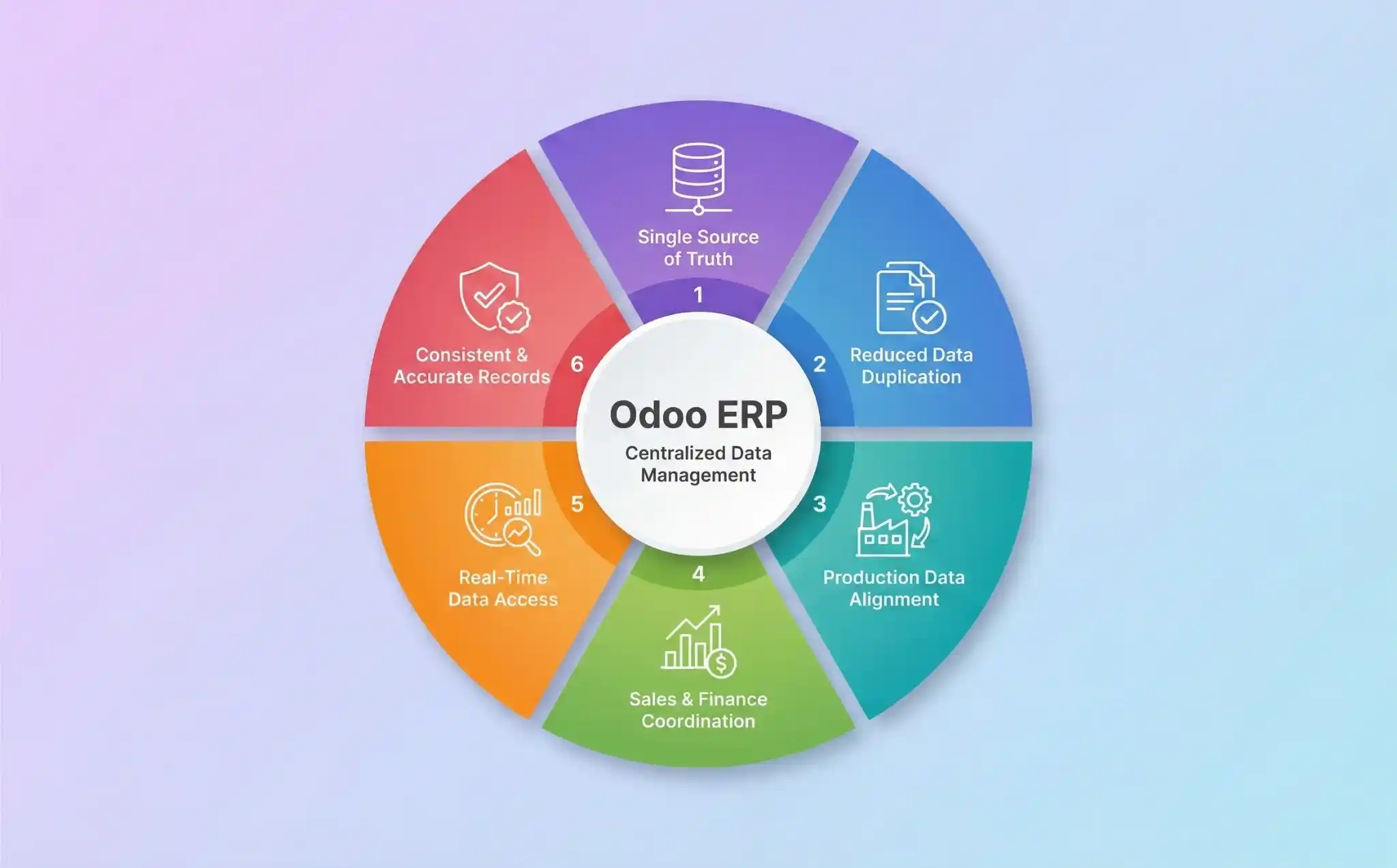

Centralized Data Management

One of the biggest advantages of Odoo for Automotive is centralized data access. Instead of working with separate systems, all departments share the same information.

Key benefits include:

A single source of truth across all teams

Reduced data duplication and inconsistencies

Better coordination between production, sales, and finance

Faster access to critical business data

Therefore, decision-making becomes more accurate and reliable.

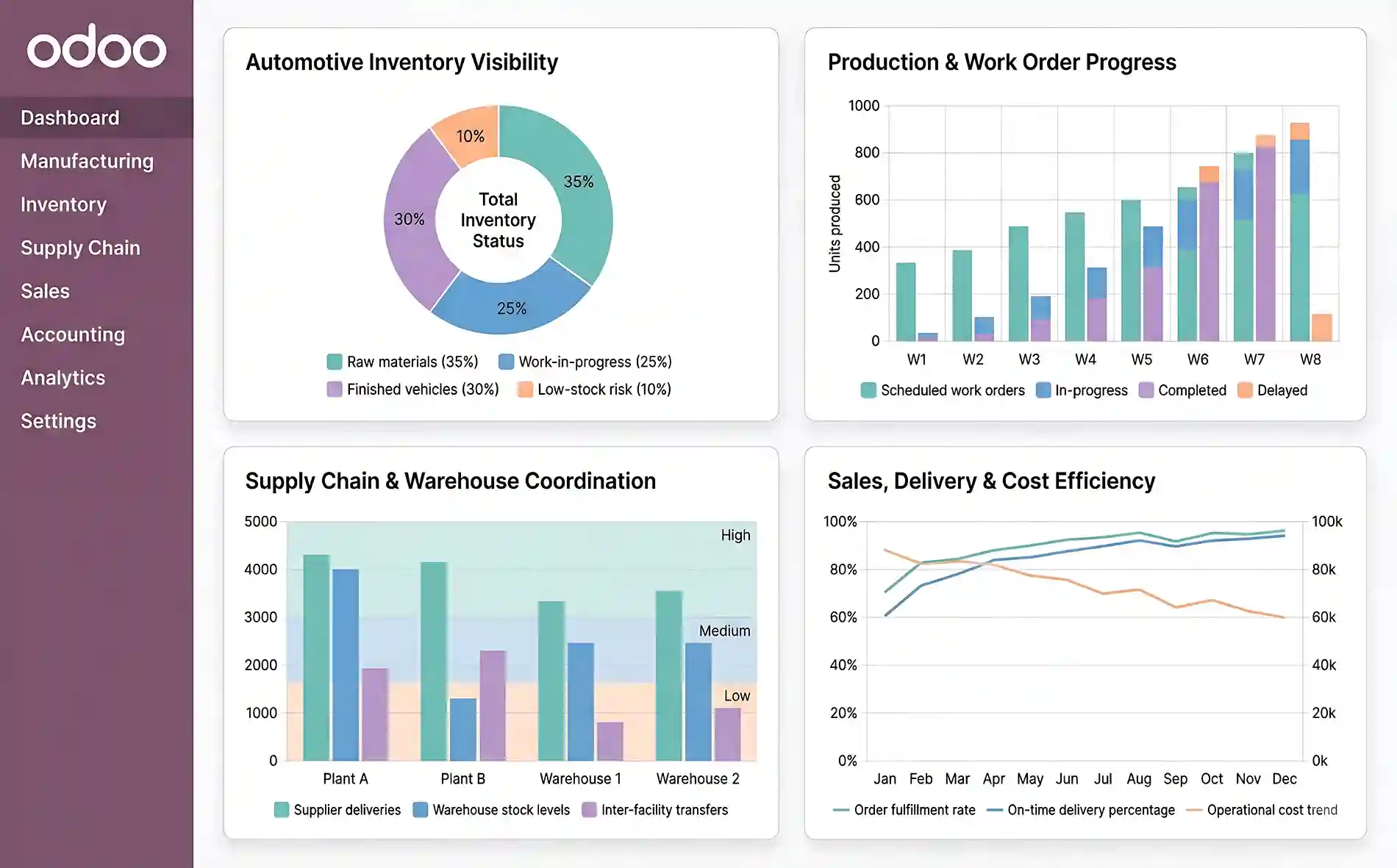

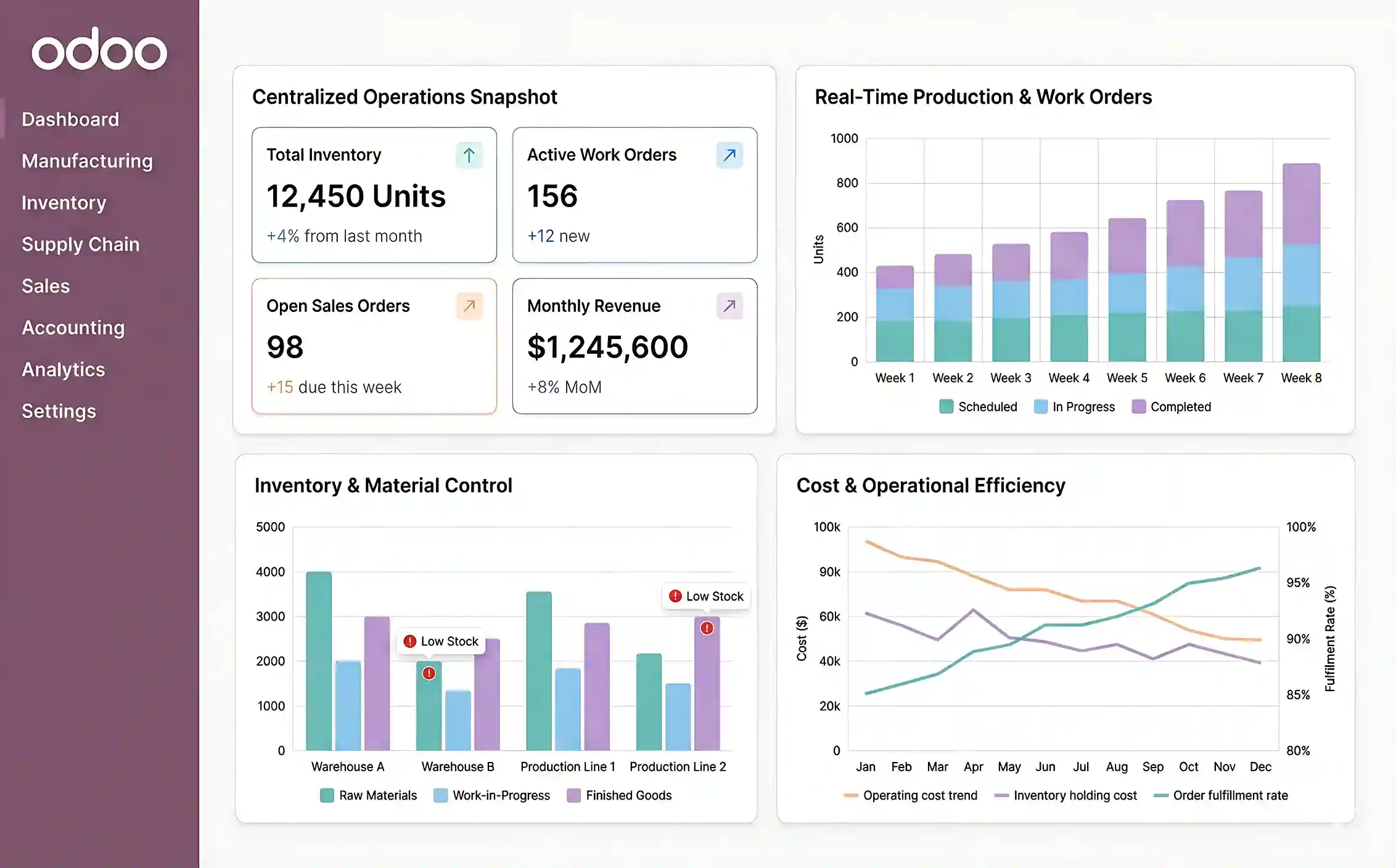

Real-Time Operational Visibility

With Odoo , businesses gain real-time visibility into daily operations. This allows managers to respond quickly to changes and challenges.

Using Odoo, automotive companies can:

Monitor inventory levels in real time

Track production and work orders

View sales performance and order status

Identify bottlenecks early

As a result, businesses can maintain smooth operations and avoid costly delays.

Improved Production and Inventory Control

Automotive improves production planning and inventory control by automating key processes.

Major advantages include:

Accurate production scheduling

Better material and resource planning

Automated inventory replenishment

Reduced stock shortages and overstocking

Consequently, companies achieve better operational stability.

Cost Reduction and Operational Efficiency

By reducing manual work and improving process accuracy, Odoo helps control operational costs.

Cost-related benefits include:

Automation of repetitive tasks

Fewer human errors

Optimized inventory holding costs

Improved financial tracking and reporting

Therefore, automotive businesses can improve profitability while maintaining quality standards.

3. Key Benefits of Odoo for Automotive Industry Operations

Odoo for Automotive provides practical and measurable benefits that help businesses manage complex automotive operations more efficiently. By using a single ERP platform, companies can streamline workflows, reduce manual effort, and improve overall operational control. As a result, teams can work more efficiently and make better decisions.

Unified Business Data Across Departments

Automotive businesses often struggle with data spread across multiple systems. A centralized ERP platform helps eliminate this challenge.

Key advantages include:

One shared data source for all departments

Reduced data duplication and inconsistencies

Improved coordination between production, sales, and finance teams

Faster access to accurate business information

Therefore, decision-making becomes more reliable and consistent.

Live Insights for Faster Decision-Making

Having access to real-time data is critical in the automotive industry, where delays can be costly.

With real-time visibility, businesses can:

Track inventory levels instantly

Monitor production progress across work orders

View order status and delivery timelines

Identify issues before they affect operations

As a result, managers can respond quickly and minimize disruptions.

Better Control Over Production and Stock

Managing production schedules and inventory levels requires accuracy and planning.

Key improvements include:

Structured production workflows

Efficient material planning

Automated stock level monitoring

Balanced inventory without excess or shortages

Consequently, production remains stable and predictable.

Optimized Costs and Resource Usage

Controlling costs is critical for long-term success in the automotive sector.

Cost optimization benefits include:

Reduced manual processing

Lower operational errors

Smarter use of inventory and resources

Clear financial tracking and reporting

Therefore, businesses improve margins while maintaining operational quality.

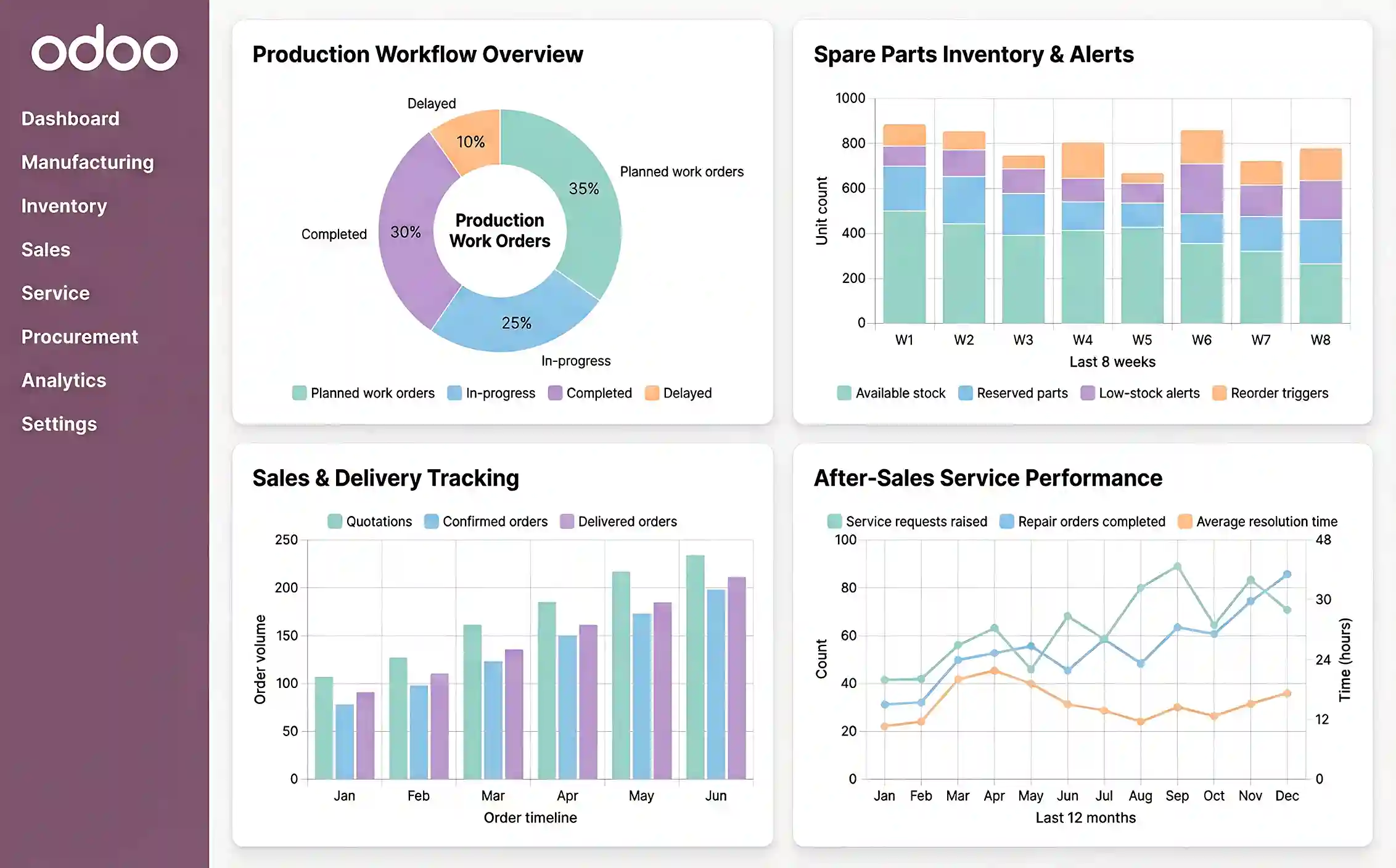

4. Practical Odoo Applications in the Automotive Industry

Odoo supports day-to-day automotive operations by connecting production, inventory, sales, and service activities in one system. As a result, businesses can manage workflows more efficiently and reduce manual effort across departments.

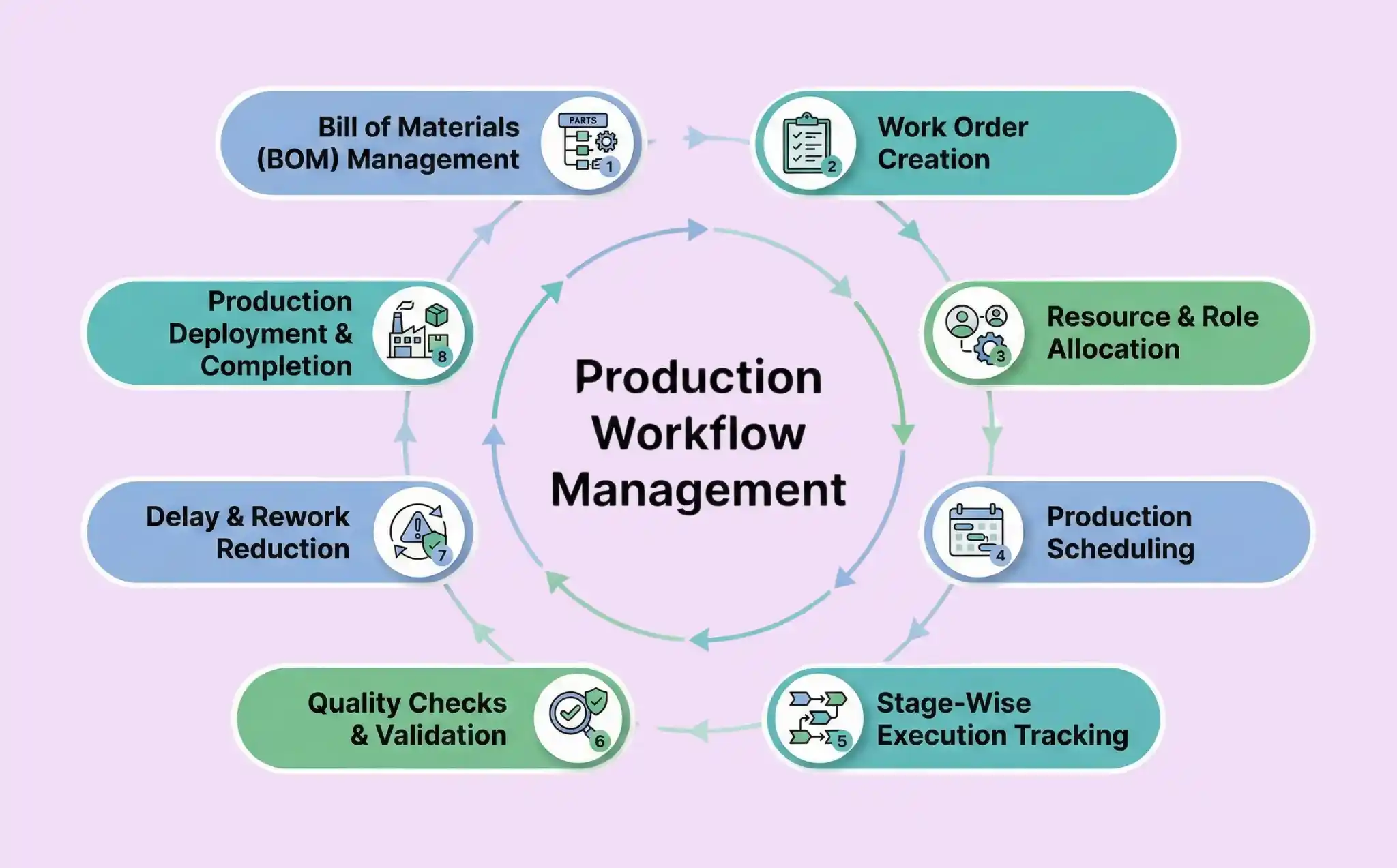

Production Workflow Management

Automotive manufacturing involves multiple steps that must stay aligned. A structured system helps maintain consistency and accuracy.

Key capabilities include:

Managing bills of materials and work orders

Planning production schedules based on demand

Tracking work progress at each stage

Reducing production delays and rework

Therefore, production teams can operate with better coordination and control.

Spare Parts and Inventory Operations

Managing spare parts is critical for automotive manufacturers and distributors.

Inventory-related benefits include:

Real-time tracking of parts and materials

Automated stock updates across locations

Alerts for low-stock situations

Improved stock accuracy and availability

As a result, businesses avoid shortages and unnecessary overstocking.

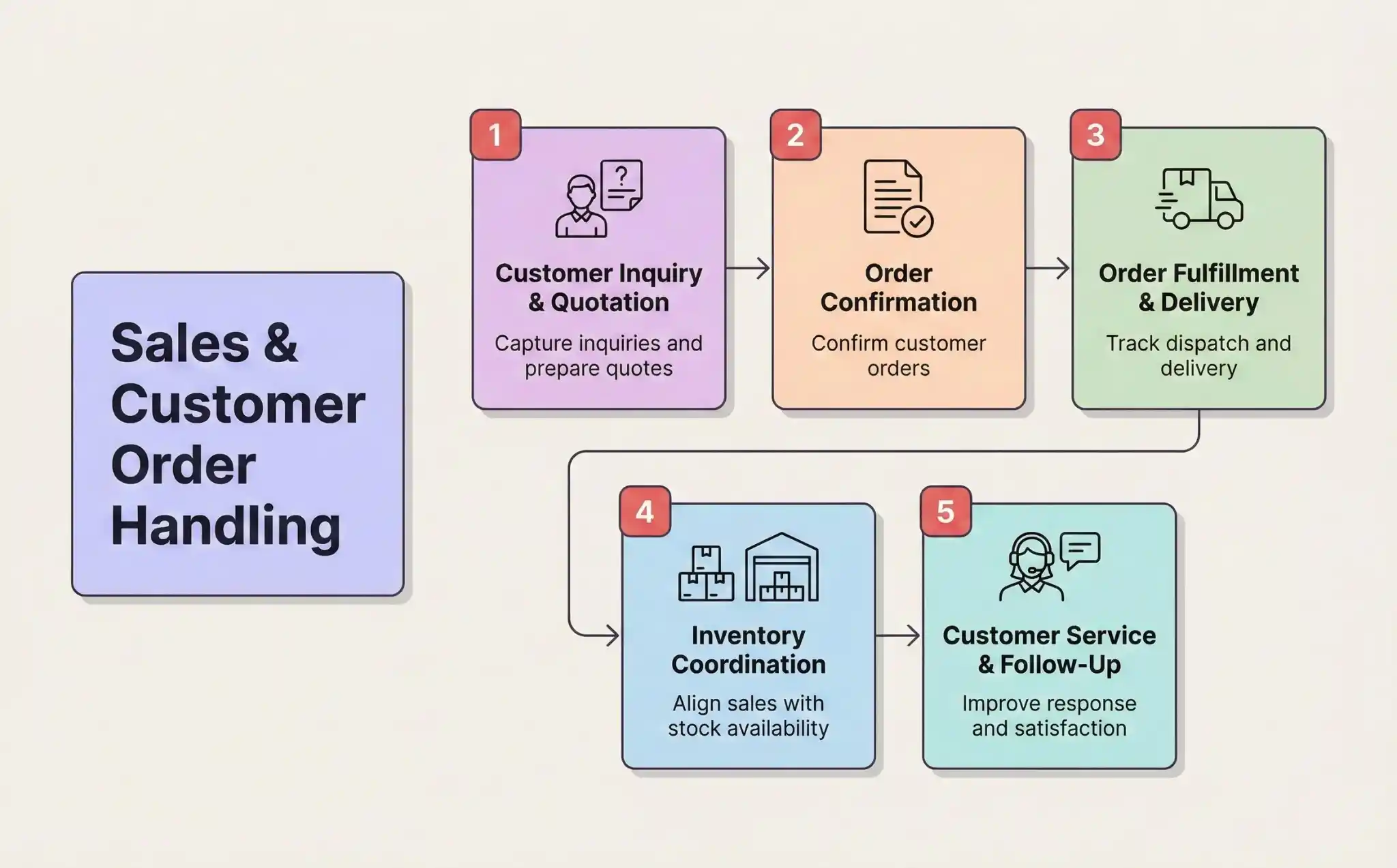

Sales and Customer Order Handling

Efficient sales operations improve customer satisfaction and revenue flow.

Sales-related applications include:

Managing customer inquiries and quotations

Tracking confirmed orders and deliveries

Coordinating sales with inventory availability

Improving response time to customer requests

Consequently, sales teams can deliver a better customer experience.

After-Sales Service and Support

After-sales service plays an important role in automotive customer retention.

Service-related features include:

Managing service requests and repair orders

Tracking warranty and maintenance history

Coordinating service teams and spare parts

Ensuring faster issue resolution

Therefore, businesses can strengthen long-term customer relationships.

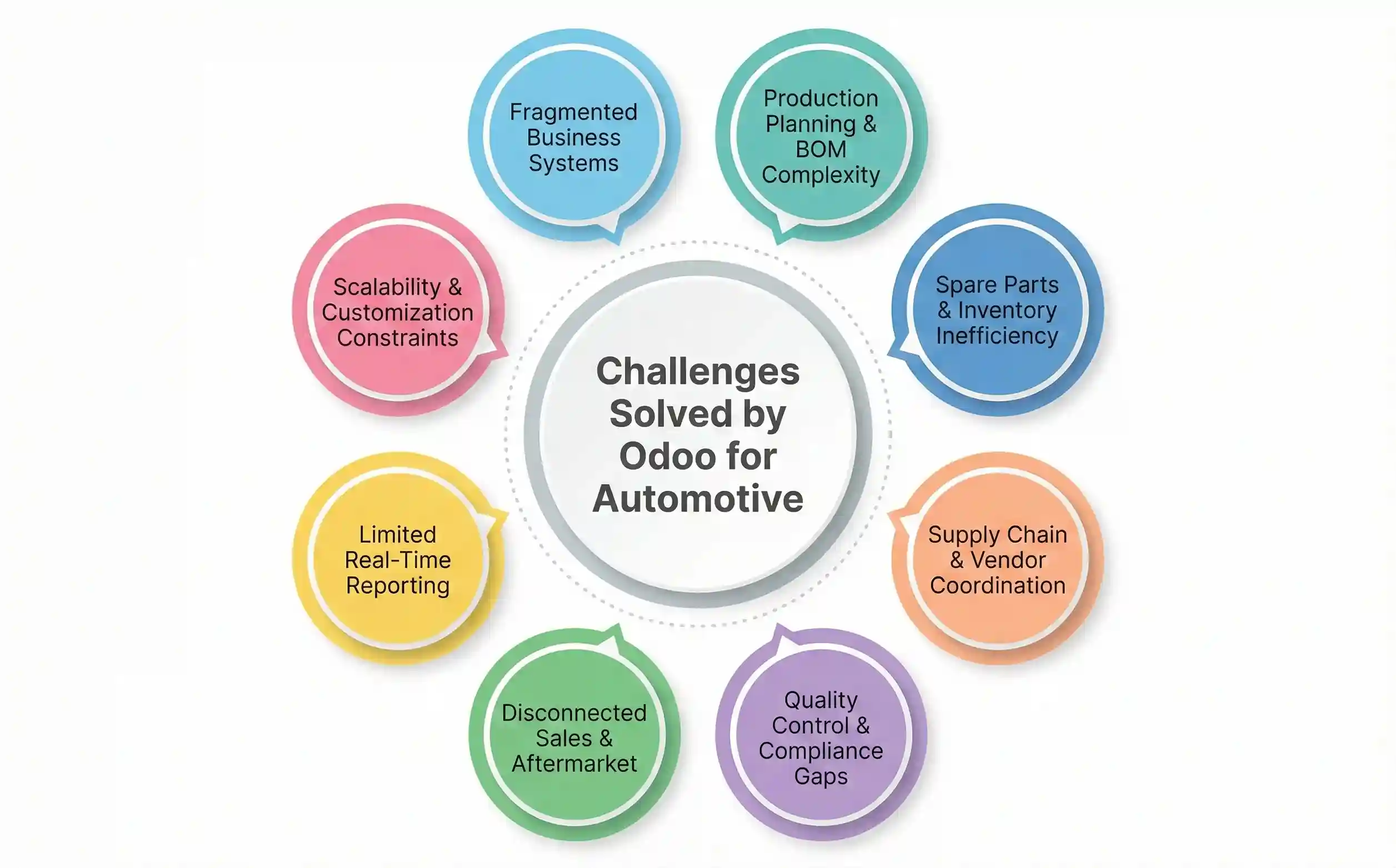

5. Common Automotive Challenges Solved by Odoo for Automotive

Odoo for Automotive addresses many of the common operational challenges faced by automotive businesses. By replacing disconnected systems with a single ERP platform, companies gain better control, visibility, and efficiency across their operations.

Eliminating Data Silos

Many automotive businesses operate with separate tools for different departments. This often leads to data gaps and miscommunication.

Odoo helps by:

Connecting all departments to one system

Ensuring consistent data across teams

Reducing duplicate data entry

Improving collaboration between functions

As a result, teams work with accurate and up-to-date information.

Managing Inventory Imbalances

Inventory imbalance is a major issue in the automotive sector, especially when dealing with spare parts.

Key improvements include:

Better tracking of stock movement

Alerts for low or excess inventory

Automated replenishment processes

Improved stock planning and forecasting

Therefore, businesses avoid shortages while keeping inventory costs under control.

Reducing Production Delays

Production delays can disrupt delivery schedules and customer satisfaction.

Odoo helps reduce delays by:

Improving production planning accuracy

Aligning material availability with schedules

Tracking progress in real time

Identifying bottlenecks early

Consequently, production processes remain more stable and predictable.

Improving Operational Transparency

Limited visibility makes it difficult for managers to make informed decisions.

With improved transparency, businesses can:

Monitor performance across departments

Access real-time reports and dashboards

Track key operational metrics

Respond quickly to operational issues

As a result, management gains better control over daily operations.

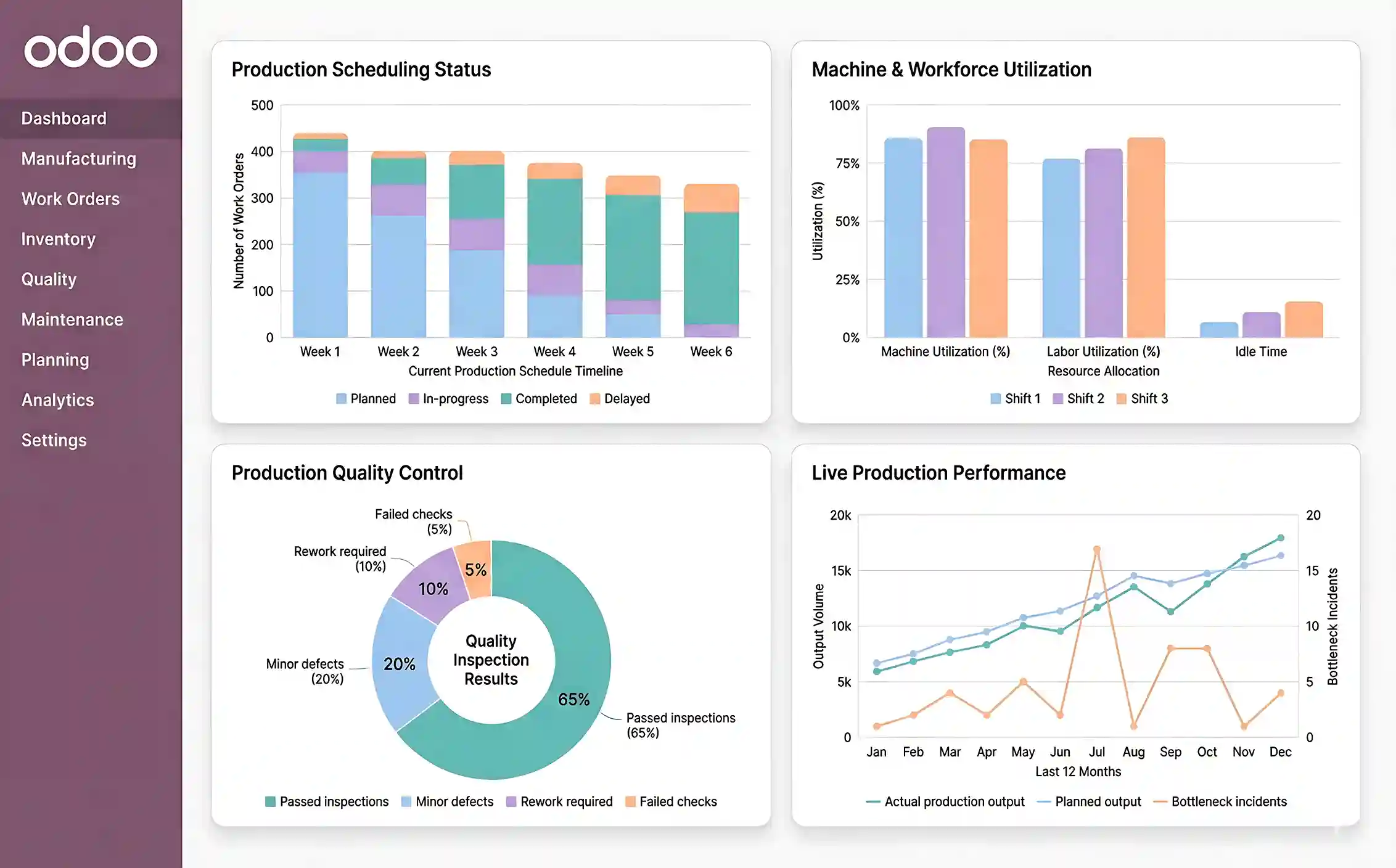

6. Odoo for Manufacturing and Production Planning

Automotive supports manufacturers by improving production planning and execution. By organizing workflows and aligning resources, businesses can maintain consistent production schedules and meet delivery commitments more effectively.

Learn More : Odoo for Automotive Manufacturing Companies

Structured Production Scheduling

Automotive production requires precise planning to avoid downtime and delays.

Key scheduling benefits include:

Creating detailed production plans

Aligning schedules with material availability

Managing work orders efficiently

Reducing unplanned production interruptions

As a result, production processes become more predictable.

Efficient Resource Allocation

Managing machines, labor, and materials efficiently is essential in automotive manufacturing.

Odoo enables:

Better utilization of machines and workforce

Clear visibility into resource availability

Reduced idle time and waste

Improved coordination across production teams

Therefore, resources are used more effectively.

Integrated Quality Checks

Quality control is critical in the automotive industry.

Quality-related improvements include:

Embedding quality checks into production workflows

Tracking inspection results at each stage

Identifying defects early

Maintaining consistent quality standards

Consequently, businesses reduce rework and improve product reliability.

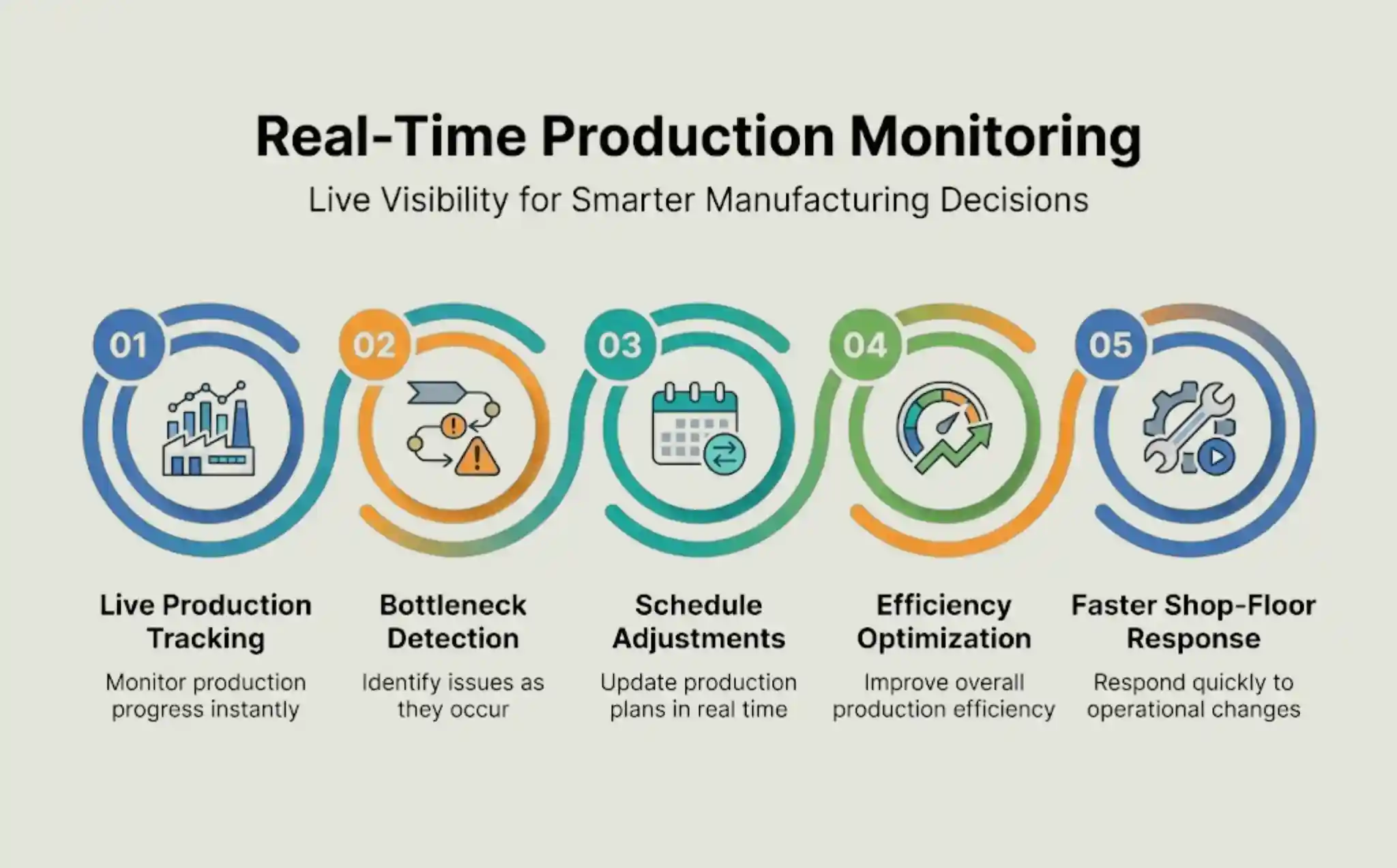

Real-Time Production Monitoring

Monitoring production in real time helps managers stay informed and proactive.

With live tracking, businesses can:

Monitor production progress instantly

Identify bottlenecks as they occur

Adjust schedules when needed

Improve overall production efficiency

As a result, teams can respond quickly to changes on the shop floor.

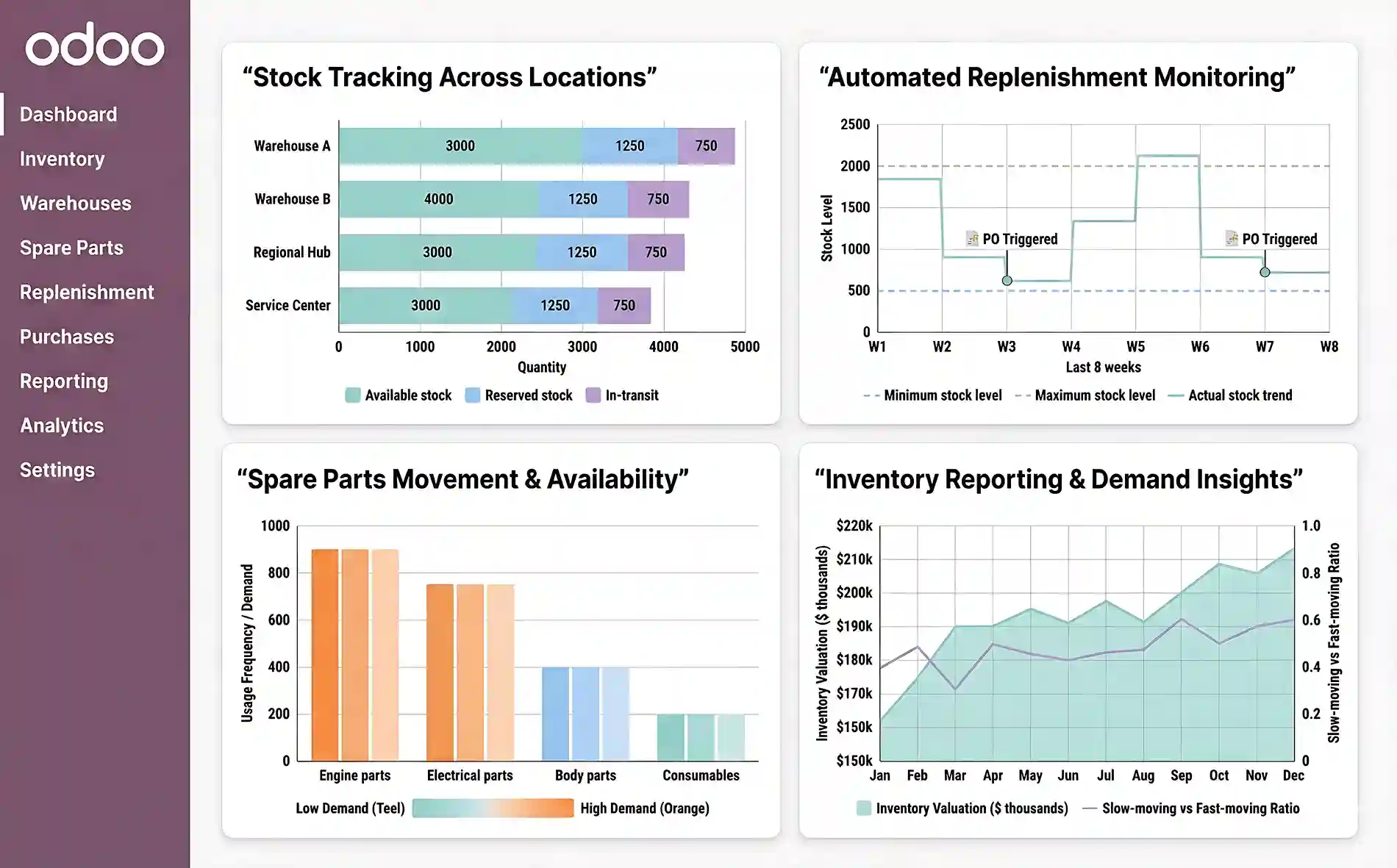

7. Inventory and Spare Parts Management Using Odoo for Automotive

Odoo helps businesses manage inventory and spare parts more accurately by centralizing stock data and automating key processes. As a result, automotive companies can maintain optimal stock levels while avoiding unnecessary costs.

Accurate Stock Tracking Across Locations

Automotive businesses often manage inventory across multiple warehouses and locations. Without proper tracking, stock errors can easily occur.

Key benefits include:

Real-time visibility of inventory levels

Accurate tracking of parts movement

Better coordination between warehouses

Reduced risk of stock mismatches

Therefore, businesses gain better control over inventory operations.

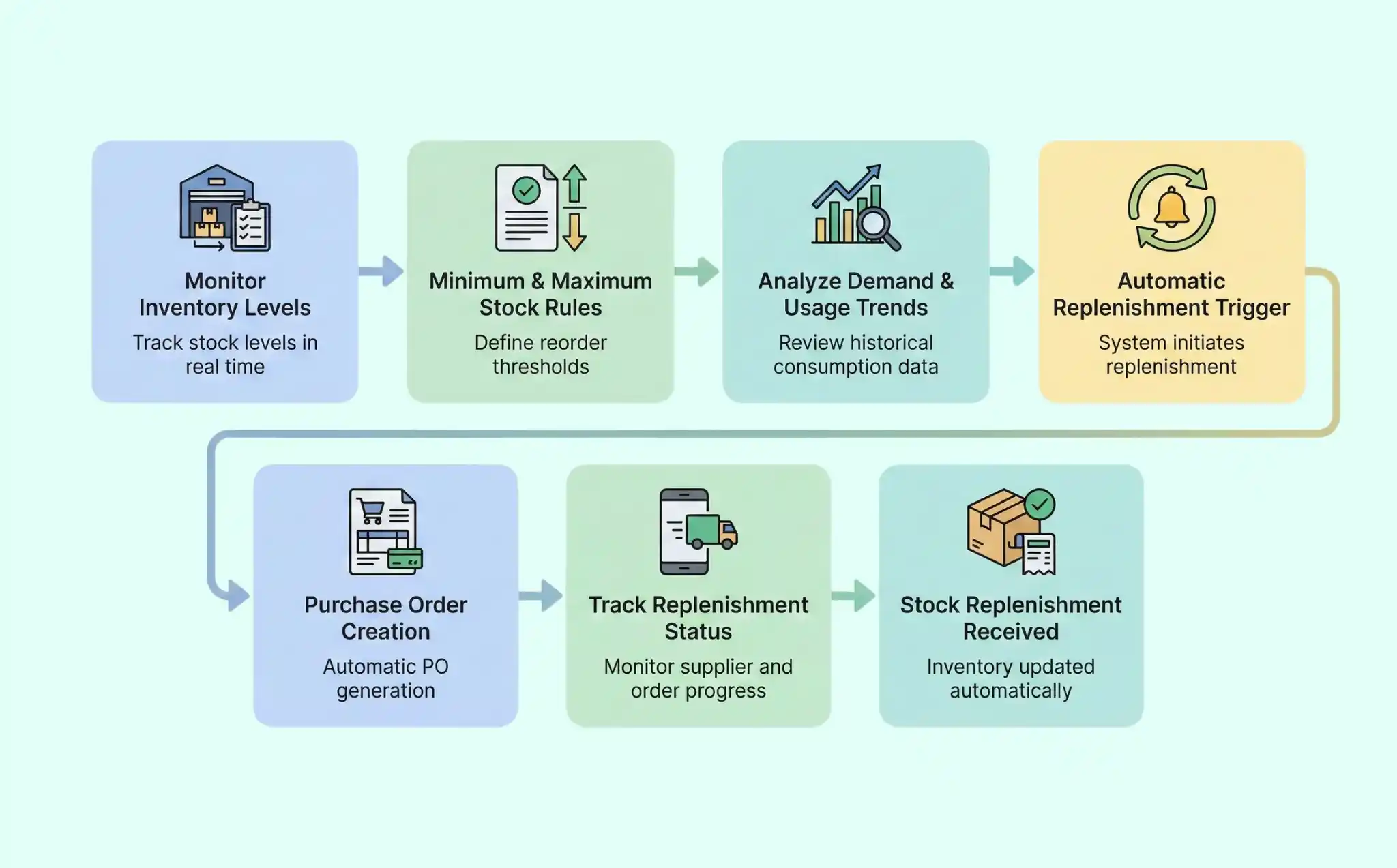

Automated Replenishment Processes

Manual stock monitoring is time-consuming and error-prone. Automation helps prevent shortages and delays.

With automated replenishment, businesses can:

Set minimum and maximum stock levels

Trigger purchase orders automatically

Reduce emergency procurement

Maintain consistent stock availability

As a result, operations continue smoothly without interruptions.

Efficient Spare Parts Handling

Spare parts management is critical in the automotive industry, especially for after-sales service.

Key improvements include:

Faster identification of required parts

Improved availability for service and repairs

Reduced excess stock of slow-moving items

Better planning for high-demand parts

Consequently, customer service quality improves while inventory costs remain controlled.

Improved Inventory Reporting

Clear inventory insights support better planning and forecasting.

Reporting benefits include:

Stock valuation reports

Movement and usage analysis

Identification of slow-moving inventory

Better demand planning

Therefore, businesses can make informed inventory decisions based on accurate data.

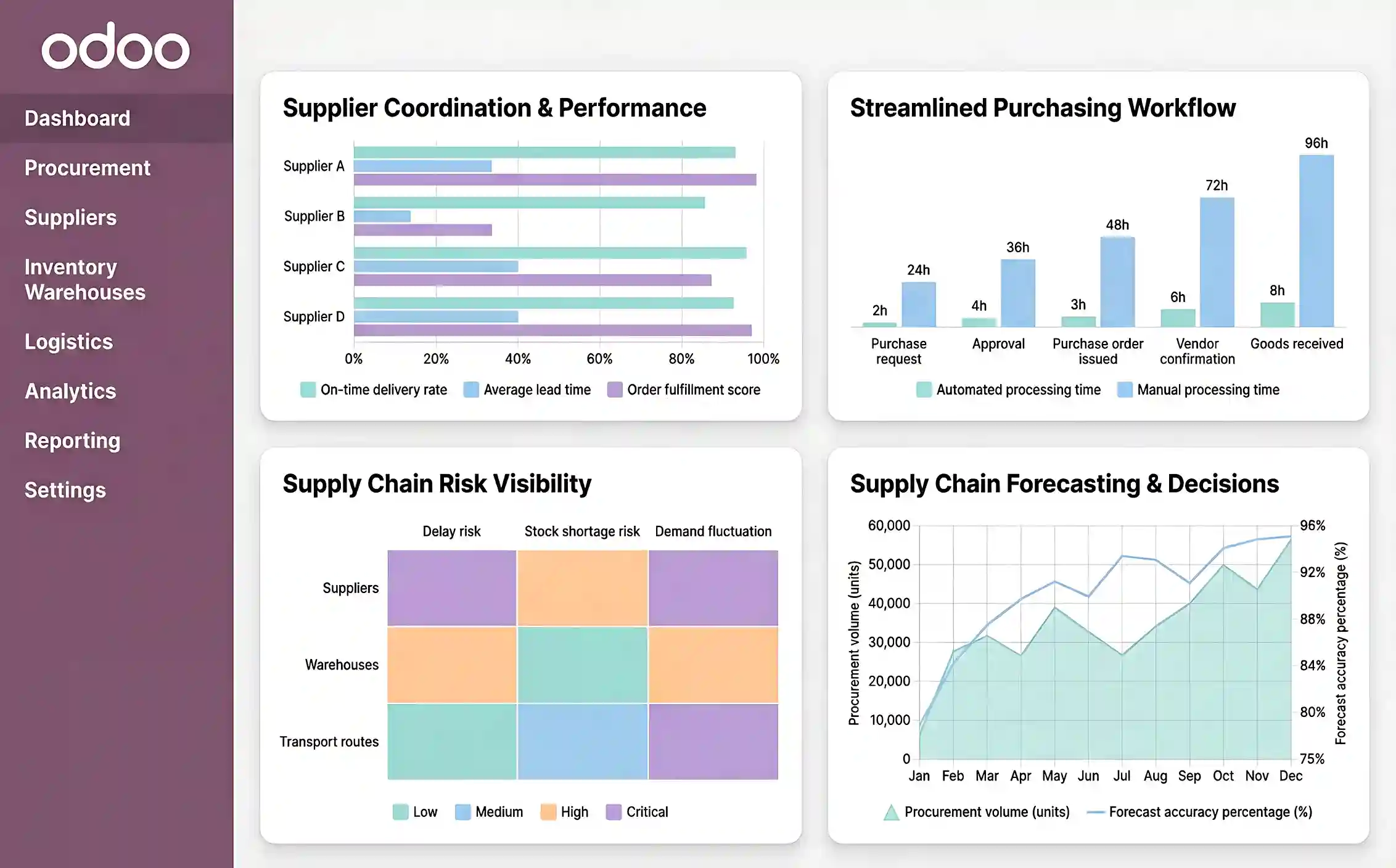

8. Improving Supply Chain Efficiency

Odoo for Automotive strengthens supply chain operations by improving coordination between purchasing, inventory, and suppliers. As a result, automotive businesses can reduce delays and maintain steady production flows.

Explore More : Streamline Automotive Finances with Odoo ERP Software

Better Supplier Coordination

Managing multiple suppliers can be challenging without a centralized system.

Key improvements include:

Centralized supplier information

Tracking delivery timelines and performance

Better communication with vendors

Reduced procurement delays

Therefore, businesses can build stronger and more reliable supplier relationships.

Streamlined Purchasing Processes

Manual purchasing often leads to errors and slow approvals.

With improved purchasing workflows, businesses can:

Automate purchase order creation

Reduce approval delays

Avoid last-minute procurement

Improve purchasing accuracy

As a result, supply chain operations become more predictable.

Reduced Supply Chain Disruptions

Unexpected disruptions can impact production schedules and customer commitments.

Odoo helps by:

Providing visibility into supply chain status

Identifying risks early

Improving demand planning accuracy

Supporting faster response to changes

Consequently, businesses experience fewer disruptions and improved operational stability.

Data-Driven Supply Chain Decisions

Accurate data plays a key role in supply chain optimization.

Decision-making benefits include:

Access to real-time procurement data

Performance analysis of suppliers

Better forecasting and planning

Continuous process improvement

Therefore, automotive companies can optimize their supply chains with confidence.

9. Financial Management and Reporting with Odoo for Automotive

| Financial Area | How Odoo Supports It | Business Benefit |

|---|---|---|

| Accounting | Automated entries and records | Fewer errors |

| Invoicing | Faster invoice generation | Improved cash flow |

| Expense Tracking | Centralized cost monitoring | Better cost control |

| Financial Reporting | Real-time reports and dashboards | Accurate decisions |

| Compliance | Organized financial records | Easier audits |

Conclusion

Odoo ERP for the automotive industry delivers a flexible, all-in-one platform that integrates production, inventory, supply chain, sales, and finance to improve efficiency and reduce costs. Automotive businesses seeking a scalable, future-ready ERP can partner with a trusted Odoo Development Company to support both current operations and long-term growth.

FAQs

How does Odoo support automotive workflows?

Odoo for Automotive integrates production, inventory, sales, and service into one system, enabling smooth and efficient workflows.

Can Odoo adapt to EV and hybrid production needs?

Yes, Odoo supports complex bills of materials and flexible processes required for EV and hybrid manufacturing.

How does Odoo help automotive service businesses?

Odoo manages service orders, spare parts, and customer history, helping improve service speed and quality.

Is Odoo suitable for tiered supplier management?

Yes, Odoo centralizes supplier data and purchase workflows, making it easier to manage multiple supplier tiers.

How does Odoo support compliance in the automotive industry?

Odoo maintains audit trails and quality records, helping businesses meet automotive regulations and standards.

Why is SDLC Corp the best choice for Odoo for Automotive implementation?

SDLC Corp is the best choice for Odoo for Automotive implementation due to its strong automotive industry experience and certified Odoo experts. The team delivers customized Odoo solutions for inventory, production, supply chain, dealerships, and after-sales operations. With end-to-end implementation, integrations, and ongoing support, SDLC Corp ensures scalable, efficient, and ROI-driven automotive ERP systems.