Introduction

Modern supply chains need real-time visibility, automation, and fast decision-making areas where traditional systems fall short. Odoo for Supply Chain unifies procurement, warehousing, logistics, and manufacturing into one smart platform, boosting efficiency and eliminating silos. Many organizations turn to a leading Odoo development company for expert implementation. As expectations rise and disruptions grow, Odoo enables greater accuracy, agility, and resilience through automation, analytics, and end-to-end synchronization.

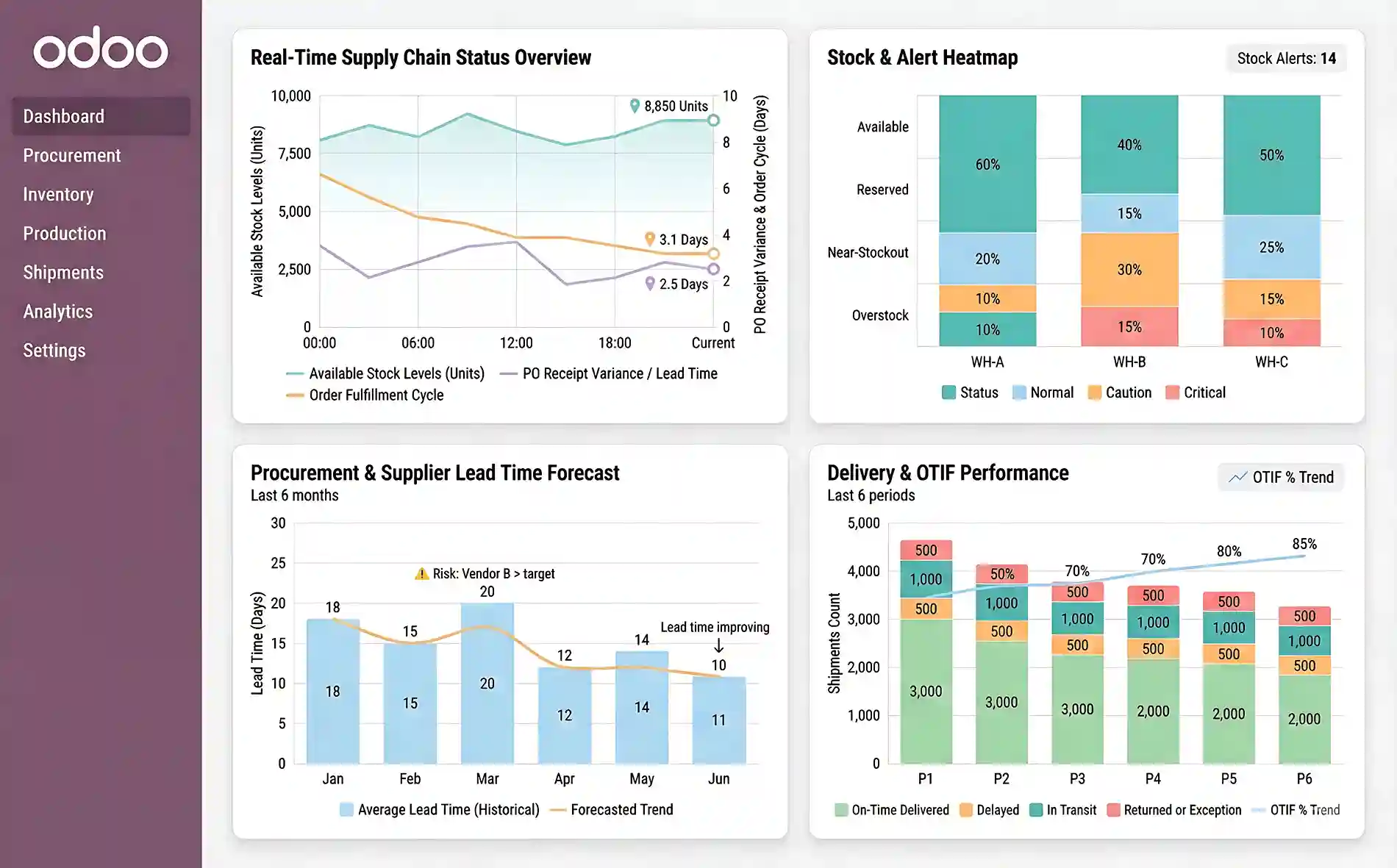

1. End-to-End Supply Chain Visibility with Odoo for Supply Chain

Modern supply chains demand real-time visibility for resilience, faster decision-making, and better customer satisfaction. Odoo for Supply Chain unifies procurement, inventory, manufacturing, warehousing, logistics, and finance into one ecosystem, removing blind spots and preventing fragmented decisions. For enterprises shifting from legacy systems, Odoo replaces isolated data and manual tracking with a unified digital command center that enables disruption prediction, performance monitoring, and fully synchronized operations.

How Odoo Builds a Unified, Real-Time Supply Chain Control Tower

Odoo integrates all supply chain modules within a single architecture, so data flows seamlessly across teams and functions. This enables:

Centralized dashboards for procurement, stock levels, production, orders, and delivery timelines

Real-time alerts for stock shortages, delays, and supply risks

Live tracking of purchase orders, vendor lead times, and supplier reliability

Instant visibility into production progress, work center loads, and material availability

Full synchronization between warehouse, logistics, and distribution workflows

Together, these capabilities form a true supply chain control tower, delivering insights that would otherwise take days or weeks to compile manually.

Why Real-Time Visibility Is Critical for Enterprise Supply Chains

Today’s supply chains are complex. Global suppliers, volatile demand, and rising logistics costs make visibility essential. With Odoo, enterprises can:

Predict disruptions before they occur

Respond quickly to inventory or supplier issues

Optimize procurement and reduce emergency purchases

Improve OTIF (On-Time In-Full) delivery performance

Enhance collaboration across internal teams and partner networks

Make instant, data-backed decisions instead of relying on outdated reports

Without this visibility, organizations face stockouts, excess inventory, delays, and operational inefficiencies—problems that Odoo is designed to reduce or remove.

Strategic Insight for Enterprises

A supply chain without real-time visibility operates in the dark. With Odoo for Supply Chain, enterprises gain:

Predictive planning instead of reactive firefighting

Synchronized information across teams and functions

A constantly updated view of global operations

Greater agility, scalability, and resilience

Moreover, Odoo’s visibility framework lays the foundation for advanced transformation, including AI-driven forecasting, automated workflows, and intelligent decision-making across the enterprise.

Location Types in Odoo Inventory

| Location Type | Description | Usage in Supply Chain |

|---|---|---|

| Vendor Location | Virtual source of goods from suppliers. | Tracks incoming liability; counterpart to Goods Receipt. |

| View Location | Hierarchical parent (e.g., “Warehouse A”). | Organizing zones/aisles; distinct from storage. |

| Internal Location | Physical storage (Shelf 1, Bin A). | Where inventory physically resides and is valued. |

| Customer Location | Virtual destination for sold goods. | Tracks goods leaving asset accounts; counterpart to Delivery. |

| Inventory Loss | Counterpart for corrections. | Balances stock adjustments during cycle counts. |

| Production | Virtual location for manufacturing. | Consumes raw materials and produces finished goods. |

| Transit Location | Temporary holding for transfers. | Tracks goods moving between two warehouses (Inter-warehouse). |

2. Inventory Optimization & Stock Intelligence with Odoo for Supply Chain

Inventory is central to supply chain performance excess stock increases costs, while shortages cause delays and unfulfilled orders. Odoo addresses both challenges with an intelligent, automated, and predictive inventory ecosystem. Instead of relying on manual updates or static safety-stock formulas, Odoo delivers real-time stock intelligence synchronized across warehouses, production centers, sales channels, and procurement pipelines. This gives supply chain leaders clear visibility and ensures inventory levels align with actual demand, production capacity, and supplier performance.

Real-Time Inventory Visibility Across All Locations

Odoo consolidates all warehouses, stock zones, and staging areas into a single inventory view. With this, teams can:

Track live stock quantities across multiple locations

Monitor stock movements, reservations, and transfers in real time

Detect material shortages early, before they impact production

Forecast replenishment needs based on actual demand patterns

Improve ATP (Available to Promise) accuracy for customer commitments

This level of visibility removes guesswork and reduces the disruptions that usually affect procurement and manufacturing workflows.

Intelligent Replenishment Powered by Data-Driven Rules

Odoo’s replenishment engine automates stock decisions using dynamic, data-driven rules that evolve with the business. Key capabilities include:

Min–max reorder rules that adapt over time

Demand-based replenishment using consumption patterns

Vendor lead-time integration for accurate reorder timing

Auto-generated Purchase Orders and Manufacturing Orders

Forecast-adjusted triggers that prevent overstocking and stockouts

Thanks to these features, inventory management moves from reactive guessing to predictive, optimized planning.

AI-Driven Forecasting & Strategic Stock Planning

Odoo’s AI models support advanced forecasting, helping enterprises anticipate inventory needs with more confidence. These models analyze:

Seasonal demand variations

Sales velocity and product lifecycle trends

Production consumption rates

Supplier performance and reliability

Long-term demand growth and expansion patterns

Based on this data, Odoo can recommend optimal safety stock to prevent disruptions during demand spikes or supply delays. For deeper insights on perishable inventory, see: Improving Perishable Supply Chains with Odoo’s Real-Time Data

Barcode/RFID-Driven Accuracy for Zero Errors

Odoo integrates seamlessly with barcode scanners, RFID readers, and modern warehouse automation technologies. This supports:

Accurate and fast picking

Error-free packing

Verified goods receipt

Smart putaway suggestions

Streamlined stock adjustments

Efficient internal transfers

These capabilities significantly reduce human error, enhance traceability, and boost overall warehouse throughput.

ATP & CTP Delivering Accurate Commitments

Odoo enhances customer satisfaction with powerful availability algorithms:

ATP (Available to Promise): Promises delivery based on current stock and confirmed replenishments.

CTP (Capable to Promise): Calculates delivery dates based on production capacity, material availability, and supplier lead times.

With ATP and CTP, businesses provide highly accurate, operationally feasible delivery commitments, improving service reliability and customer trust.

3. Strategic Procurement & Supplier Management with Odoo for Supply Chain

Procurement is the backbone of an efficient supply chain, and issues like poor supplier quality, inaccurate lead times, and unexpected delays can disrupt everything from production to customer satisfaction. Odoo transforms procurement from a transactional task into a strategic, automated, intelligence-driven process focused on material availability, cost control, and supplier performance. Modern procurement demands real-time data, supplier collaboration, contract compliance, and predictive planning all of which Odoo enables through its integrated procurement ecosystem.

Unified Procurement Workflows & Automated Purchasing

Odoo standardizes procurement by tightly integrating it with inventory, production, sales, logistics, and finance. This ensures all purchasing decisions reflect current and forecasted operational needs.

Odoo enables:

Automatic Purchase Order creation when inventory hits defined thresholds

RFQ automation based on demand forecasts and consumption trends

Vendor comparison tools evaluating price, lead time, and reliability

Approval hierarchies to control spending and enforce compliance

Integrated contract and SLA management for consistent procurement governance

By automating routine tasks, procurement teams can shift their focus from operational firefighting to cost optimization and supplier strategy.

Supplier Performance Monitoring & Scorecards

Supplier performance directly affects production efficiency and customer outcomes. Odoo provides real-time analytics and scorecards to evaluate:

On-time delivery performance

Lead time accuracy

Supplier pricing trends over time

Quality inspection pass/fail ratios

Responsiveness to RFQs and communication

These insights enable enterprises to negotiate stronger contracts, improve supplier collaboration, eliminate unreliable vendors, and build long-term strategic partnerships.

Lead Time Intelligence & Predictive Procurement

Odoo continuously analyzes supplier behavior and adjusts procurement planning in real time. Capabilities include:

Predicting late deliveries based on historical patterns

Adjusting safety stock for unreliable suppliers

Auto-updating lead times dynamically according to actual performance

Recommending alternate suppliers when risk indicators appear

This predictive intelligence protects organizations from stockouts, reduces emergency purchases, and ensures production continuity.

End-to-End Vendor Collaboration & Communication

Odoo enhances supplier engagement through a fully integrated vendor portal that allows suppliers to:

View assigned purchase orders

Confirm deliveries and expected dates

Upload invoices electronically

Submit quality or compliance documentation

Communicate updates in real time

This eliminates back-and-forth emails, accelerates approvals, and strengthens supplier transparency.

Seamless Integration with Inventory & Manufacturing

Odoo ensures procurement operates in perfect harmony with operational workflows:

Inventory triggers RFQs based on real-time levels

BoM shortages automatically generate purchase requirements

Manufacturing lead times influence purchase timelines

Sales forecasts adjust procurement quantities dynamically

This end-to-end integration ensures procurement aligns with production schedules, demand planning, and order fulfillment commitments.

Strategic Impact on Supply Chain Operations

With Odoo for Supply Chain, procurement becomes:

- Predictive instead of reactive

- Transparent instead of fragmented

- Data-driven instead of subjective

- Collaborative instead of siloed

Organizations leveraging Odoo achieve:

- Better supplier relationships

- Reduced procurement cycle time

- Lower purchase costs through strategic negotiation

- Higher production reliability

- Significantly fewer supply disruptions

For additional reading on optimizing procurement inside Odoo, explore: Optimizing Supply Chain Management with Odoo ERP

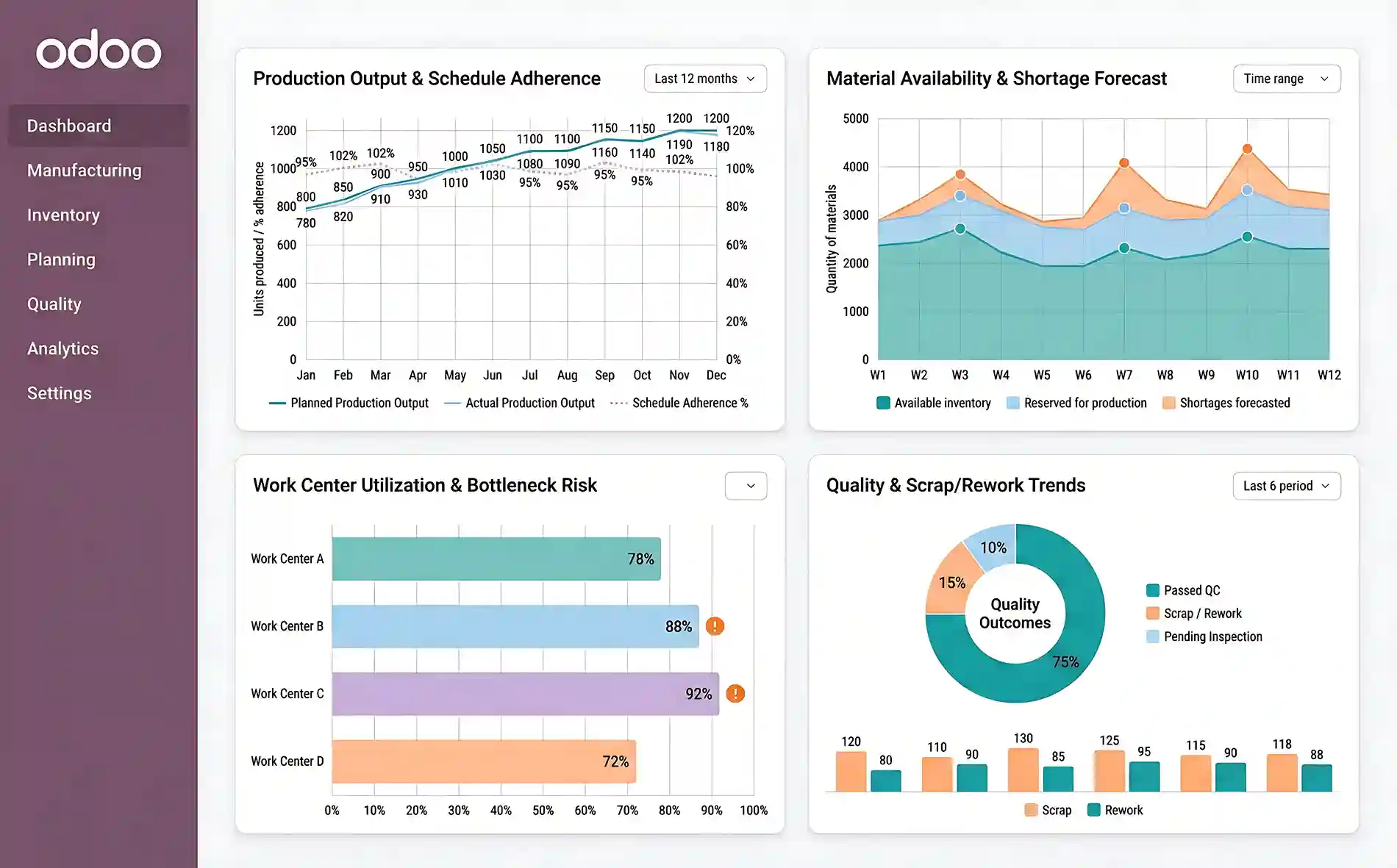

4.Manufacturing, MRP & Production Excellence with Odoo for Supply Chain

Manufacturing is the core engine of the supply chain, and disruptions from material shortages to machine downtime or quality issues create costly ripple effects across operations. Odoo’s advanced Manufacturing (MRP) system unifies production planning, material availability, work orders, capacity scheduling, quality control, and maintenance into one seamless workflow. With Odoo, manufacturers move from fragmented, reactive processes to predictive, data-driven production, ensuring stable operations and consistent product availability.

Integrated MRP Engine for Real-Time Production Orchestration

Odoo’s MRP module unifies every stage of the production cycle, giving manufacturers real-time visibility into:

What materials are required and in what quantities

When materials must be available to prevent delays

Which work centers or machines have available capacity

What bottlenecks or constraints may impact scheduling

How long each step of the production process will take

This integration replaces spreadsheet-based planning with an intelligent, automated system reducing manual intervention and eliminating planning errors that slow manufacturing performance.

Accurate Production Planning with Master Production Schedule (MPS)

Odoo’s MRP module unifies every stage of the production cycle, giving manufacturers real-time visibility into:

What materials are required and in what quantities

When materials must be available to prevent delays

Which work centers or machines have available capacity

What bottlenecks or constraints may impact scheduling

How long each step of the production process will take

This integration replaces spreadsheet-based planning with an intelligent, automated system reducing manual intervention and eliminating planning errors that slow manufacturing performance.

Material Requirements Planning (MRP) that Prevents Stockouts

Ensuring material availability is one of the most critical—and difficult challenges in manufacturing. Odoo’s MRP engine prevents these disruptions with powerful automated capabilities:

Breaks down Bills of Materials (BoM) into exact component requirements

Checks availability across all warehouses and stock zones

Calculates shortages and triggers replenishment

Generates internal transfers, manufacturing orders, or purchase orders

Synchronizes material flow with production timelines

This ensures that raw materials and components arrive precisely when needed, eliminating emergency procurement and unnecessary production downtime.

Strategic Impact on Supply Chain Resilience

By adopting Odoo, manufacturers achieve measurable improvements, including:

20–40% faster production scheduling and planning cycles

Significant reduction in machine downtime and process delays

Lower scrap, rework, and quality-related losses

Higher yield and throughput efficiency across work centers

More reliable order fulfillment and shorter lead times

Perfect alignment between procurement, inventory, and production

Manufacturing becomes predictable, scalable, quality-driven, and fully synchronized with the broader supply chain transforming operational performance at every level. For deeper insights into Odoo’s manufacturing capabilities, explore: The Role of Odoo in Complex Manufacturing Supply Chains

5. Warehouse Optimization & Fulfillment Automation with Odoo for Supply Chain

Warehousing has shifted from basic storage to a strategic execution hub where speed, accuracy, and flexibility are essential. With tighter delivery windows and complex fulfillment models, automation and real-time intelligence are now critical. Odoo elevates warehouse operations with smart routing, live stock movements, barcode precision, and integrated fulfillment workflows. By connecting warehousing with procurement, manufacturing, and logistics, Odoo ensures a smooth flow of goods from inbound to outbound, reducing delays, minimizing manual effort, and boosting overall throughput.

Real-Time Warehouse Visibility & Intelligent Stock Movements

Odoo gives warehouses complete live visibility into every zone, shelf, and staging area, enabling teams to operate with precision and speed. With real-time intelligence, warehouse staff can instantly view:

Current stock availability by bin, batch, lot, or serial number

Live picking progress and priority fulfillment queues

Incoming shipments with expected delivery times and delay alerts

Stock aging and rotation rules for FEFO/FIFO-based optimization

Automated replenishment triggers for fast-moving or low-stock zones

This eliminates manual stock checks, reduces unnecessary walking time, and prevents misplaced inventory dramatically increasing warehouse productivity.

Comparison Table Traditional Warehouse vs. Odoo-Optimized Warehouse

| Functionality | Traditional Warehouse | Warehouse with Odoo for Supply Chain |

|---|---|---|

| Inventory Tracking | Manual, error-prone | Real-time, barcode-enabled |

| Picking Methods | Basic picking only | Batch, wave, cluster & zone picking |

| Routing | Static, inefficient | Smart routing with automated paths |

| Replenishment | Reactive, delayed | Automated triggers based on demand |

| Visibility | Limited to spreadsheets | Full dashboard with live updates |

| Accuracy | Medium | Very high (near-zero errors) |

Advanced Picking Methods for Faster Fulfillment

Odoo provides multiple advanced picking workflows that allow warehouses to choose the fulfillment strategy best suited to volume, product mix, and operational priorities. These methods dramatically reduce walking time, balance workloads, and improve order accuracy.

Batch Picking: Ideal for high-volume operations, batch picking allows workers to pick items for multiple similar orders simultaneously. This reduces repetitive movement and consolidates common picks, greatly speeding up fulfillment.

Wave Picking: Odoo groups picking tasks into time-based waves that align with truck departures, shipping deadlines, or priority customer orders. This ensures warehouse operations stay synchronized with logistics schedules.

Cluster Picking: Workers use carts or totes to pick multiple orders in a single route, optimizing travel paths and enabling faster handling of diverse SKU orders.

Zone Picking: The warehouse is divided into zones, with staff assigned to specific areas. Each order moves from zone to zone, minimizing worker movement and improving throughput during peak hours.

Cross-Docking: For fast-moving or backordered items, Odoo supports cross-docking—moving goods directly from receiving to outbound shipments without storing them. This reduces handling costs and accelerates delivery.

Together, these strategies reduce labor requirements, minimize travel time, and significantly increase order processing speeds.

Automated Replenishment & Stock Level Optimization

Odoo ensures that forward pick locations and high-frequency zones never run dry. The system continuously monitors inventory and triggers replenishment based on:

Minimum/maximum stock thresholds

Forecasted demand and seasonal trends

Vendor lead times and reliability

Production dependencies

Historical consumption patterns

Automated replenishment eliminates last-minute stock shortages, reduces picker delays, and helps maintain consistent fulfillment flow across all shifts.

Inbound & Outbound Coordination for Zero Bottlenecks

Odoo unifies receiving, quality checks, picking, packing, loading, and dispatch into a single, fully orchestrated workflow. This eliminates bottlenecks and ensures warehouse activities remain synchronized from start to finish.

Key capabilities include:

Scheduled Receiving with ASN Visibility: Helps warehouses plan labor and space before goods arrive.

Automated Quality Checks: Ensures received items meet specifications before being stored or forwarded to production.

Smart Packing Logic: Determines packing based on order contents, weight, dimensions, or shipping destinations.

Optimized Loading Workflows: Aligns dock assignments and loading sequences with truck routes and delivery deadlines.

Real-Time Shipping & Carrier Integration: Instantly updates shipping status and labels, improving transparency and speed.

This coordinated execution enhances dock productivity, prevents space congestion, and ensures error-free outbound shipments.

Warehouse KPIs & Performance Analytics

Odoo provides a powerful analytics engine that enables warehouse leaders to track, benchmark, and optimize performance using real-time KPIs such as:

Picking accuracy and error rates

Dock-to-stock processing time

Average pick path distance

Inventory turnover ratio

Cost per order fulfilled

Order cycle time

Employee productivity and efficiency metrics

These insights empower operations managers to redesign warehouse layouts, improve staff allocation, enhance workflow efficiency, and maintain high SLA compliance.

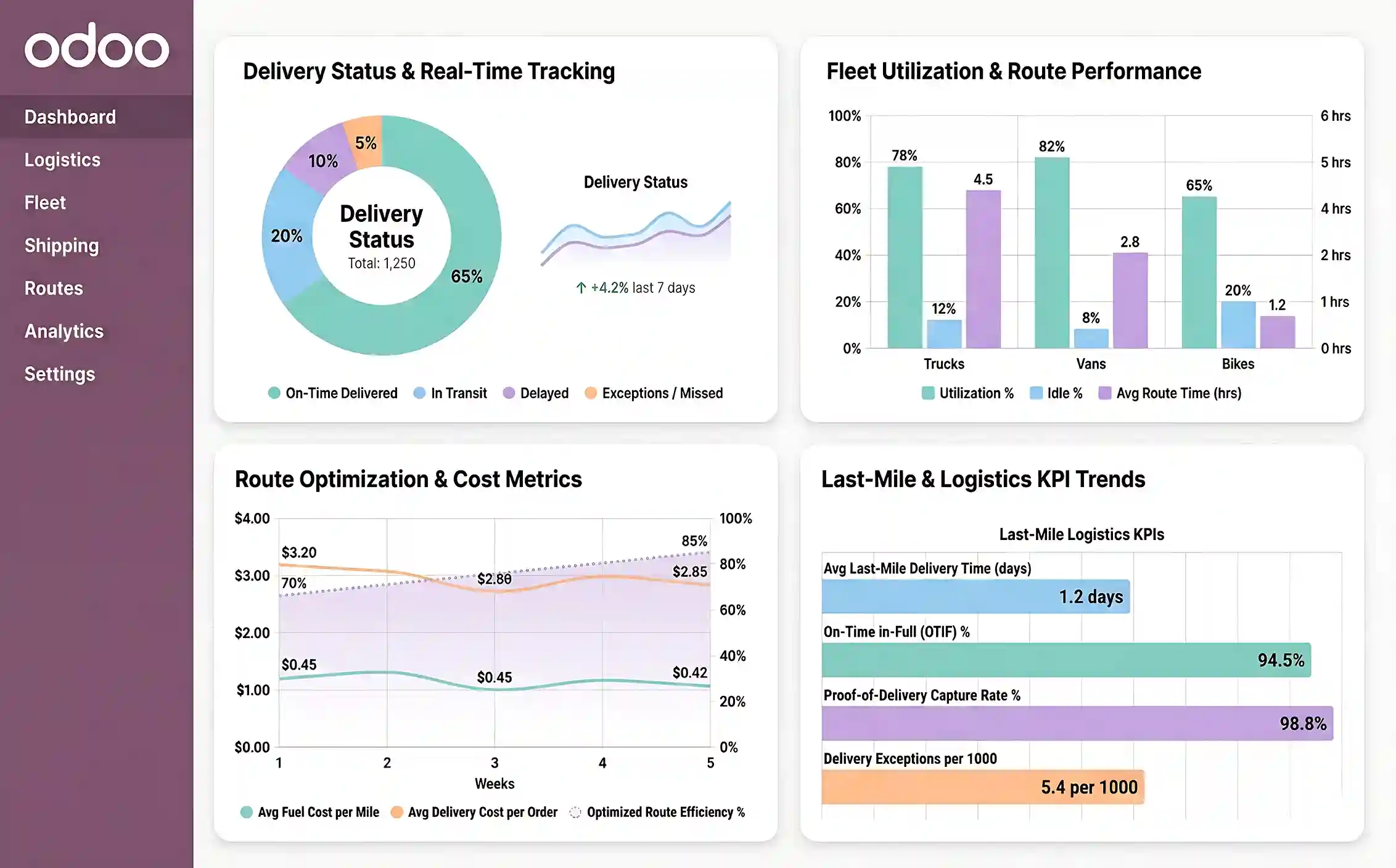

6. Logistics, Transportation & Distribution Management with Odoo for Supply Chain

Transportation and distribution are among the most costly and complex supply chain functions. With rising freight costs, unpredictable routes, and demanding customer expectations, enterprises need smarter logistics systems. Odoo meets this need by unifying shipment planning, fleet management, carrier integration, and delivery tracking in one platform.

Instead of relying on manual coordination, Odoo transforms logistics into an automated, data-driven distribution engine linking transportation planning, fleet operations, shipping workflows, and last-mile execution for faster deliveries, fewer errors, and complete visibility.

Unified Logistics Operations for Seamless Movement of Goods

Odoo centralizes all logistics activities dispatching, routing, packaging, labeling, carrier selection, and shipment tracking within one integrated system. This eliminates manual handoffs, duplicated entries, and communication gaps between warehouse teams, fleet managers, and carriers.

With Odoo’s logistics workflows, organizations can:

View all ready-to-ship orders in a single dashboard

Assign shipments to carriers or internal fleets with ease

Track delivery status in real time

Automatically generate shipping labels and documentation

Manage freight costs, route information, and delivery exceptions

This holistic approach dramatically reduces delays, minimizes bottlenecks, and improves operational precision.

Advanced Route Planning & Optimization

Route planning directly impacts delivery timelines, transportation costs, and fleet productivity. Odoo uses dynamic routing logic to analyze:

Delivery destinations

Distance and estimated travel time

Vehicle capacity and load constraints

Fuel efficiency metrics

Traffic conditions (via integrated services)

Priority or time-sensitive shipments

Based on these variables, Odoo generates optimized routes that reduce fuel consumption, lower operational costs, and maximize delivery volume per vehicle.

GPS Tracking & Real-Time Delivery Monitoring

Odoo integrates with GPS devices, telematics platforms, and third-party logistics systems to deliver complete visibility into delivery operations.

Enterprises can:

Track real-time vehicle locations

Monitor driver behavior and route adherence

Receive alerts for delays, diversions, or missed stops

View delivery progress on an interactive dashboard

Provide customers with live shipment updates

This level of transparency strengthens customer trust, ensures SLA compliance, and enhances delivery accuracy.

Freight Cost Management & Carrier Selection

Freight spending can spiral without proper control. Odoo gives organizations the tools to optimize and manage costs effectively:

Compare carrier rates instantly

Choose carriers based on speed, reliability, or cost

Allocate freight charges automatically to specific orders

Track historical spending to identify savings opportunities

Support rate negotiations through data-driven insights

This enables enterprises to reduce transportation costs and maintain full financial oversight.

Automated Shipment Labeling & Documentation

Odoo automates the creation of all required shipping documentation, including:

Shipping labels

Packing slips

Bills of Lading (BoL)

Export and compliance documents

Delivery notes

This removes manual paperwork, reduces errors, and speeds up outbound processes significantly.

Last-Mile Delivery Optimization

The last mile accounts for up to half of total shipping costs, making it one of the most critical logistics stages. Odoo enhances last-mile execution through:

Real-time driver assignment and task updates

Mobile proof-of-delivery (POD) capture

Automated customer notifications with delivery windows

Geolocation-based delivery confirmation

Intelligent rerouting for missed or delayed deliveries

These capabilities increase delivery accuracy, reduce turnaround time, and elevate the end-customer experience.

7. Demand Forecasting & Predictive Analytics with Odoo for Supply Chain

Demand forecasting sits at the strategic core of the supply chain. When forecasts are wrong, companies face stockouts, excess inventory, emergency buying, production issues, and higher logistics costs. Odoo for Supply Chain turns forecasting into a predictive, data-driven discipline using historical data, seasonal patterns, AI algorithms, market signals, and operational metrics.

As a result, the supply chain can anticipate demand, optimize production capacity, improve procurement accuracy, and stabilize inventory levels before disruptions occur.

AI-Driven Demand Forecasting for Smarter Decision-Making

Odoo’s AI-powered forecasting engine evaluates a wide range of parameters to generate precise demand projections:

Historical sales and consumption patterns

Seasonal fluctuations and festival cycles

Customer buying behavior and order frequency

Promotion and marketing-driven demand spikes

Production throughput and work center efficiency

Supplier performance and lead-time variability

Market trends and volatility indicators

Using these signals, Odoo generates forecasts that directly inform production schedules, procurement plans, safety stock levels, and replenishment strategies allowing companies to respond proactively rather than reactively.

Integrated Sales, Inventory & Manufacturing Forecast Alignment

Forecast accuracy improves dramatically when departments operate from a centralized, synchronized model. Odoo aligns planning across sales, inventory, procurement, and manufacturing:

Sales forecasts automatically trigger procurement and production

Real-time inventory prevents overproduction or shortages

Supplier lead-time reliability adjusts forecast accuracy

Work center capacity shapes feasible production schedules

Logistics availability aligns with projected delivery loads

This unified approach eliminates the bullwhip effect, where small changes in customer demand create major upstream distortions.

Predictive Planning for Procurement & Production

Odoo ties forecasting directly into procurement and manufacturing workflows, creating a seamless planning engine:

Automatic generation of purchase suggestions

Production scheduling based on upcoming forecasted quantities

Material availability checks to avoid production halts

Forward planning of manufacturing cycles and shift schedules

Strategic supplier engagement based on long-term volume visibility

Procurement gains negotiation power through predictable ordering cycles, while manufacturing benefits from stable production flows and better resource allocation.

Strategic Impact on the Supply Chain

Enterprises that adopt Odoo’s forecasting and predictive analytics experience measurable improvements:

30–50% reduction in stockouts

Lower excess inventory and reduced carrying costs

Stronger supplier relationships through long-term planning

Increased production efficiency with fewer interruptions

Higher fulfillment reliability and improved customer satisfaction

Logistics capacity optimized to match demand fluctuations

With Odoo, the supply chain becomes predictive, stable, and strategically aligned not just reacting to demand, but shaping it through intelligent planning.

Conclusion

Odoo for Supply Chain unifies procurement, inventory, manufacturing, warehousing, and logistics into one intelligent ecosystem, improving accuracy, agility, and operational efficiency. Its automation and predictive insights help businesses reduce delays and respond quickly to market changes.

For smooth implementation and long-term success, enterprises rely on experts like SDLC Corp’s Odoo Consulting Services, ensuring optimized configurations and sustained performance.

FAQs

1. How does Odoo for Supply Chain improve operational visibility?

Odoo unifies procurement, inventory, manufacturing, warehousing, and logistics into one real-time system, giving teams full visibility into stock levels, supplier performance, production status, and delivery timelines. This helps reduce delays and supports faster, data-driven decision-making.

2. Can Odoo for Supply Chain support multi-company and global operations?

Yes. Odoo supports multi-warehouse, multi-currency, multi-language, and multi-company setups, making it ideal for organizations operating across different regions with diverse regulatory and operational requirements.

3. Does Odoo offer demand forecasting for supply chain planning?

Yes. Odoo uses AI-driven forecasting to analyze past demand, seasonality, and lead times, helping businesses optimize stock levels, plan procurement, and align production with market needs.

4. How does Odoo improve warehouse and logistics performance?

Odoo automates picking, packing, routing, and replenishment while offering barcode/RFID accuracy and carrier integration. This speeds up fulfillment, reduces errors, and improves delivery reliability.

5. Why is SDLC Corp the best choice for Odoo for Supply Chain or Odoo For Enterprises implementation?

SDLC Corp excels due to its extensive experience, industry-specific knowledge, and technical expertise. Their proven consulting methodology and strong record of successful Odoo project delivery ensure scalable, efficient, and customized implementations.

6. Is Odoo customizable for different supply chain industries?

Yes. Odoo can be tailored for manufacturing, retail, FMCG, automotive, pharmaceuticals, and more through configurable workflows, custom modules, quality rules, and integration options.

7. Can Odoo integrate with external logistics and 3PL systems?

Yes. Odoo integrates seamlessly with 3PLs, carriers, GPS systems, and warehouse automation tools using APIs, enabling smooth coordination between internal operations and external logistics partners.