Introduction

The rise of Digital Twins in AI is bridging the gap between the physical and digital worlds. A digital twin is a virtual replica of a real object, process, or system, powered by AI, IoT sensors, and real-time data.This combination enables businesses to simulate, predict, and optimize performance with unprecedented accuracy.

Today, digital twins are transforming industries such as manufacturing, healthcare, automotive, and energy. By reducing downtime, improving efficiency, and driving innovation, they have become a cornerstone of digital transformation strategies. The market momentum is undeniable.

Forecasts predict the digital twin industry will surpass $110 billion by 2028, growing at a CAGR of over 30%. Clearly, digital twins are not just a passing trend they are the future of AI-driven industries, shaping how organizations will operate, compete, and innovate in the years to come. Organizations looking to leverage this technology can benefit by collaborating with experienced AI developers and solution providers

1. What Are Digital Twins?

A Digital Twin is a virtual replica of a physical system, process, or product. It serves as a bridge between the physical and digital worlds by enabling organizations to monitor, analyze, and optimize real-world assets in real time.

This technology is more than just a simulation. Unlike traditional models, digital twins are dynamic constantly updated through live data streams, ensuring accuracy and actionable insights.

Core Components of Digital Twins

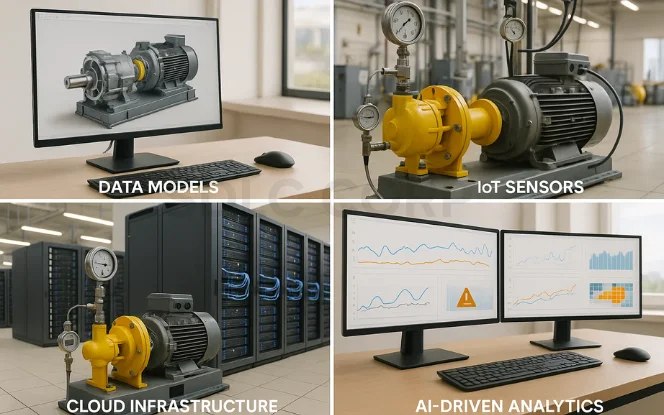

A successful digital twin relies on multiple advanced technologies working together:

- Data Models – Provide the foundational structure for replicating physical systems in a digital environment.

- IoT Sensors – Capture real-time data from equipment, machines, or processes and feed it into the digital model.

- Cloud Infrastructure – Stores and processes vast amounts of data while offering scalability and remote accessibility.

- AI-Driven Analytics – Applies machine learning and predictive algorithms to extract insights, detect anomalies, and simulate future outcomes.

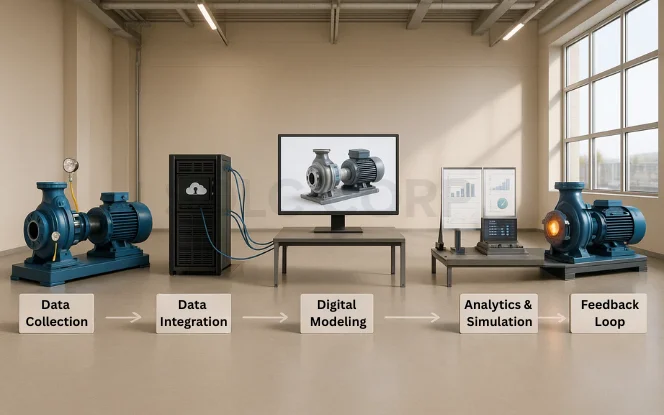

How Digital Twins Work

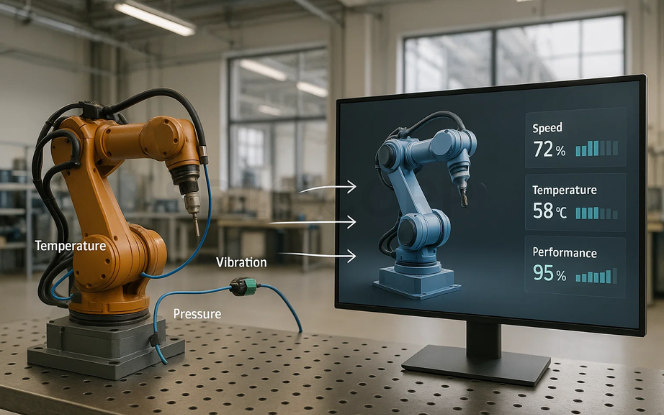

The core functionality of digital twins revolves around real-time data exchange. Here’s how the process typically works:

- Data Collection – IoT sensors embedded in physical assets capture metrics such as temperature, pressure, performance, or energy consumption.

- Data Integration – The captured data is transmitted to cloud platforms, where it is processed and structured into a usable format.

- Digital Modeling – The processed data continuously updates the virtual model, ensuring it reflects the current state of the physical asset.

- Analytics & Simulation – AI and advanced analytics run simulations, predict failures, and recommend improvements.

- Feedback Loop – Insights are sent back to operators or automated systems, enabling smarter decision-making and proactive actions.

By seamlessly connecting the physical and digital realms, digital twins empower industries to improve efficiency, reduce downtime, and innovate with confidence.

2. Role of AI in Digital Twins

AI transforms digital twins from static replicas into intelligent, self-learning systems that analyze real-time data, detect patterns, and make autonomous decisions with minimal human input.

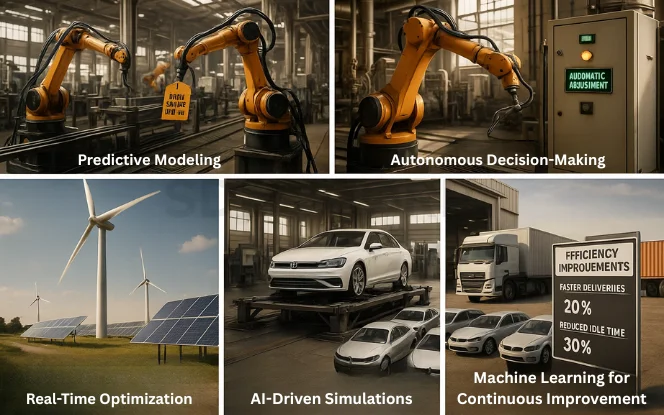

How AI Enhances Digital Twins

AI transforms digital twins from simple monitoring tools into intelligent, predictive ecosystems. Here are the key roles it plays:

- Predictive Modeling – AI algorithms analyze historical and real-time data to forecast potential failures, performance issues, or maintenance needs before they occur.

- Autonomous Decision-Making – By leveraging machine learning models, digital twins can automatically adjust parameters or trigger corrective actions without manual input.

- Real-Time Optimization – AI continuously processes live sensor data to fine-tune operations, improving efficiency, energy usage, and resource allocation.

- AI-Driven Simulations (What-If Scenarios) – Advanced simulations allow organizations to test hypothetical situations, such as system overloads or process changes, and predict outcomes without risking the real asset.

- Machine Learning for Continuous Improvement – Every interaction between the physical and digital twin feeds new data into the model, enabling ongoing learning and adaptation for higher accuracy over time.

Why AI Matters in Digital Twin Technology

Without AI, digital twins would remain passive replicas. By adding intelligence, they become proactive problem-solvers capable of predicting, simulating, and optimizing at scale. This integration not only reduces downtime but also unlocks opportunities for innovation, cost savings, and sustainable operations across industries such as manufacturing, healthcare, and smart cities.

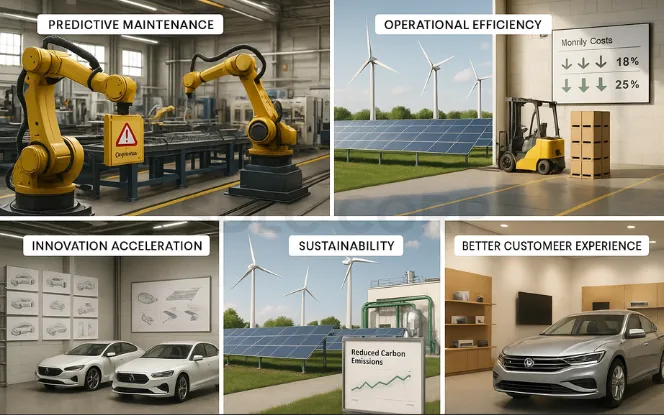

3. Benefits of Digital Twins in AI

The integration of Artificial Intelligence (AI) with digital twins delivers significant advantages across industries. By combining real-time data with intelligent analytics, organizations can unlock efficiencies, reduce costs, and drive smarter decision-making.

Key Benefits

Predictive Maintenance – AI forecasts equipment issues before failure, reducing downtime and repair costs.

Operational Efficiency – Real-time optimization enhances productivity and energy usage.

Cost Reduction – Preventive strategies and optimized resource allocation cut unnecessary expenses.

Innovation Acceleration – AI-driven simulations allow safe testing of new designs, processes, and strategies.

Sustainability – Digital twins enable greener operations by minimizing waste and improving energy efficiency.

Better Customer Experience – Personalized products and services can be developed through predictive insights.

Benefits of AI-Driven Digital Twins

- Predictive Maintenance: Minimize downtime and repair costs

- Operational Efficiency: Boost productivity and resource utilization

- Cost Reduction: Eliminate unnecessary expenses

- Innovation: Accelerate testing and product design

- Sustainability: Cut waste and energy consumption

By adopting AI-driven digital twins, businesses not only improve operational resilience but also gain a competitive edge in innovation and sustainability. These benefits translate directly into practical applications across industries.

Check Out : Generative AI for Smart Cities

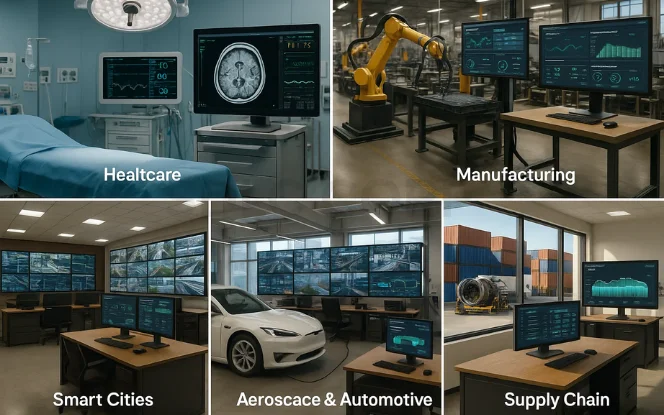

4. Real-World Applications of Digital Twins

Digital twins, when combined with AI and IoT, are transforming industries by creating smarter, more efficient, and predictive systems. Their ability to mirror physical environments in real time makes them invaluable across multiple sectors.

Key Applications Across Industries

Healthcare – Patient-specific digital twins are used for personalized treatment planning, surgical simulations, and monitoring chronic conditions. This helps doctors predict outcomes more accurately and reduce medical risks.

Manufacturing – Digital twins optimize production lines by analyzing sensor data, identifying bottlenecks, and predicting equipment maintenance needs. AI-driven models ensure minimal downtime and improved product quality.

Smart Cities – Urban planners leverage digital twins to simulate energy consumption, traffic flow, and infrastructure performance. AI algorithms allow cities to reduce congestion, optimize utilities, and enhance sustainability.

Aerospace & Automotive – In aerospace, digital twins replicate aircraft systems for flight testing and predictive maintenance. In the automotive sector, they power autonomous driving simulations and vehicle performance optimization.

Supply Chain – Businesses use digital twins to forecast demand, model logistics, and identify supply chain inefficiencies. This results in cost reduction, faster deliveries, and more resilient operations.

Read Also: Generative AI for Supply Chain

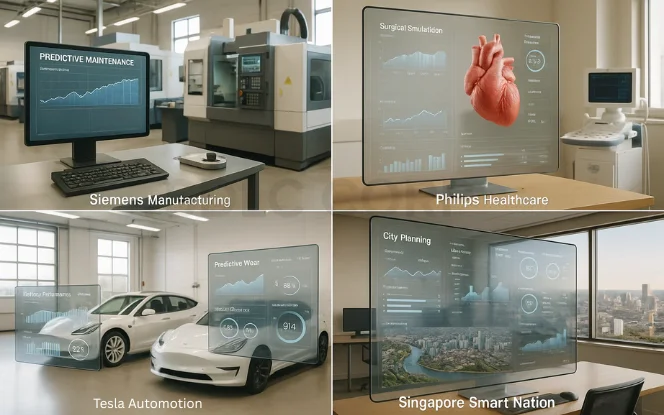

5. Case Studies & Industry Examples

Real-world adoption of AI-powered digital twins demonstrates measurable business value. Leading companies and governments are already leveraging this technology to improve efficiency, sustainability, and innovation.

Siemens (Manufacturing) – Implemented AI-driven predictive maintenance using digital twins. The result was a 20% reduction in production downtime, saving millions in operational costs.

Philips (Healthcare) – Developed patient-specific cardiac digital twins to simulate surgeries and optimize treatment plans. This innovation led to higher success rates in complex heart surgeries and improved patient outcomes.

Tesla (Automotive) – Uses digital twins to optimize battery performance by simulating real-world conditions, predicting wear, and improving energy efficiency. This has helped Tesla maintain leadership in electric vehicle innovation.

Singapore Smart Nation Project (Smart Cities) – Leveraged AI-powered digital twins to simulate citywide energy usage, urban mobility, and traffic flows. The initiative enhanced sustainability efforts and improved traffic management in one of the world’s busiest urban hubs.To better understand their unique advantages, let’s compare digital twins with traditional simulation models.

6. Digital Twins vs. Traditional Simulation Models

For decades, organizations have relied on traditional simulation models to predict performance, test designs, or understand system behavior. While useful, these models are inherently static they use a fixed set of inputs, run a single simulation, and provide insights only for that moment in time.

In contrast, digital twins with AI are dynamic, continuously evolving representations of real-world systems. By combining real-time IoT data, cloud infrastructure, and AI-driven analytics, digital twins offer a much deeper, ongoing understanding of assets and processes.

Why Traditional Simulation Models Fall Short

- Static and One-Time Use – Once built, traditional models cannot update automatically without manual intervention.

- Limited Scope – They capture a snapshot of the system but do not reflect ongoing changes.

- Approximate Results – Accuracy is constrained by assumptions made during initial modeling.

- Manual Decision-Making – Insights require human interpretation and action, slowing responsiveness.

How Digital Twins with AI Excel

- Dynamic and Real-Time – Digital twins continuously receive live data, ensuring models reflect the current state of assets.

- AI-Driven Learning – Machine learning algorithms adapt models automatically, improving precision over time.

- Scalable Architecture – Cloud and edge computing allow digital twins to grow with business needs, from single machines to entire factories or cities.

- Autonomous Optimization – AI enables systems to make predictive adjustments and even execute corrective actions without manual input.

Side-by-Side Comparison

| Aspect | Traditional Simulation | Digital Twins with AI |

|---|---|---|

| Data Flow | One-time input | Real-time continuous feedback |

| Adaptability | Limited | Highly adaptive with AI/ML |

| Scalability | Low | High (cloud & edge computing) |

| Accuracy | Approximate | Near real-time precision |

| Decision-Making | Manual | Autonomous, AI-driven |

The Key Difference

Traditional simulations are useful for static analysis for example, testing a product design under fixed conditions. However, digital twins represent a paradigm shift: they are living models that grow smarter with every data point, continuously aligning with reality and enabling proactive, intelligent decision-making.

7. Challenges in Adopting Digital Twins in AI

While AI-powered digital twins offer tremendous value, their adoption comes with significant challenges. Organizations must carefully address these hurdles to realize the full potential of this transformative technology.

Key Challenges

Data Security & Privacy Risks :- Digital twins rely on vast amounts of sensitive data, often collected from connected devices and cloud platforms. Breaches or weak encryption can expose businesses to cybersecurity threats and compliance violations.

Example: In healthcare, HIPAA regulations make it difficult to deploy patient-specific digital twins without strict safeguards.

Integration with Legacy Systems :- Many organizations still depend on outdated, siloed systems that are not designed to connect with modern IoT and AI platforms. This makes it challenging to ensure smooth data flow across old and new technologies.

Example: Traditional factories with decades-old machines often struggle to retrofit IoT sensors for real-time monitoring.

High Infrastructure Costs :- Building a digital twin ecosystem requires investment in advanced sensors, cloud storage, edge computing, and AI analytics. For small and mid-sized businesses, these costs can be prohibitive.

Example: A mid-tier manufacturer may need to spend millions upfront before seeing measurable ROI from digital twin adoption.

Workforce Skill Gaps :- Successful deployment requires expertise in AI, IoT, cloud computing, and data science. Many companies face a shortage of professionals who can design, implement, and manage digital twin platforms

Example: Even large enterprises often struggle to find engineers skilled in both operational technology (OT) and IT integration.

8. Future Trends of Digital Twins with AI

The future of digital twins enhanced by AI is promising, with emerging technologies pushing the boundaries of what is possible. As industries evolve, new trends will shape the way organizations design, monitor, and optimize physical and digital environments.

Key Future Trends

Convergence of Metaverse and Digital Twins (5–7 years) :- Digital twins will become a core element of the metaverse, enabling immersive simulations of factories, cities, and even human bodies. This convergence will let businesses and governments test large-scale scenarios in virtual worlds before committing to real-world execution.

Example: Smart cities could model traffic congestion in the metaverse, reducing infrastructure risks before construction begins.

Generative AI for Design Automation (2–4 years) :- Generative AI will accelerate prototyping by allowing digital twins to automatically generate optimized product designs, workflows, and infrastructure layouts. This will shorten time-to-market and boost innovation across industries.

Example: Automotive companies could use generative digital twins to test thousands of design variations before building a single prototype.

Sustainable Digital Twins for Green Innovation (3–5 years, ongoing) :-As global sustainability goals rise, digital twins will help organizations monitor energy use, emissions, and waste in real time. With AI-driven insights, businesses can move closer to net-zero operations and greener cities.

Regulatory Context: New standards such as the EU’s CSRD and upcoming SEC climate disclosure rules will push industries to adopt digital twins as compliance tools.

AI-Powered Edge Computing for Real-Time Analytics (already emerging, scaling in 2–3 years) :- As IoT devices generate massive data volumes, edge-enabled digital twins will process information closer to the source. This reduces latency, cuts costs, and enables faster decisions.

Example: In autonomous vehicles, edge-based digital twins will instantly analyze sensor data to improve safety and responsiveness.

Conclusion

Digital twins, empowered by Artificial Intelligence, are reshaping how industries design, monitor, and optimize complex systems. From healthcare and manufacturing to aerospace and smart cities, these virtual replicas deliver real-time insights, predictive analytics, and large-scale innovation. For organizations, adopting AI-driven digital twins is no longer optional it is a strategic imperative. Early adopters will lead the way in efficiency, sustainability, and customer experience, defining the next era of digital transformation.

As this evolution continues, AI-powered solutions will remain at the core fueling smarter decision-making, unlocking new business models, and ensuring long-term resilience in an increasingly dynamic world. To explore tailored strategies and practical implementations, visit our AI Consulting Services.

FAQs

Q1: What is a digital twin in AI?

A digital twin is a virtual model of a physical system, product, or process, powered by real-time data, IoT sensors, and AI-driven analytics.

Q2: How does AI improve digital twins?

AI enhances digital twins through predictive modeling, real-time optimization, autonomous decision-making, and simulation of what-if scenarios.

Q3: What are the main benefits of digital twins with AI?

They offer predictive maintenance, cost reduction, improved efficiency, faster innovation, and sustainable operations.

Q4: Which industries are using AI-powered digital twins?

Key industries include healthcare, manufacturing, smart cities, aerospace, automotive, and supply chain management.

Q5: What challenges do businesses face when adopting digital twins?

The biggest challenges are data security, integration with legacy systems, high infrastructure costs, and workforce skill gaps.