Introduction

Generative AI in manufacturing startups is becoming a key driver of innovation. By combining AI’s ability to generate designs and predict outcomes with the precision of manufacturing processes, startups can cut costs, reduce risks, and improve speed.

AI-driven manufacturing innovation now plays a role in product design, predictive maintenance, and smart factory systems. In addition, it helps startups optimize supply chains to remain competitive despite limited resources.

This blog explains how generative AI product design, AI-powered supply chain optimization, predictive maintenance, and smart factory AI integration support startups in building efficient and future-ready businesses.

The Role of Generative AI in Manufacturing Startups

Startups often face challenges such as high costs, limited staff, and tight deadlines. Generative AI provides solutions by creating designs, testing them digitally, and predicting outcomes.

How startups benefit:

- Faster design-to-prototype cycles.

- Lower production and material costs.

- Flexibility to adjust when market needs shift.

- Ability to simulate changes before committing resources.

Generative AI and Early Manufacturing Operations:

Manufacturing startups often operate with limited data, small teams, and tight margins. Generative AI helps by supporting early-stage tasks such as process documentation, demand analysis, and design iteration. Many teams begin by exploring Generative AI development services to build models that can adapt to their specific production workflows and data constraints.

For example, when using generative AI product design, a startup can ask the AI to optimize a part for both cost and strength. The system generates multiple options, and blockchain or simulation tools verify their feasibility. As a result, startups save time while ensuring reliable results.

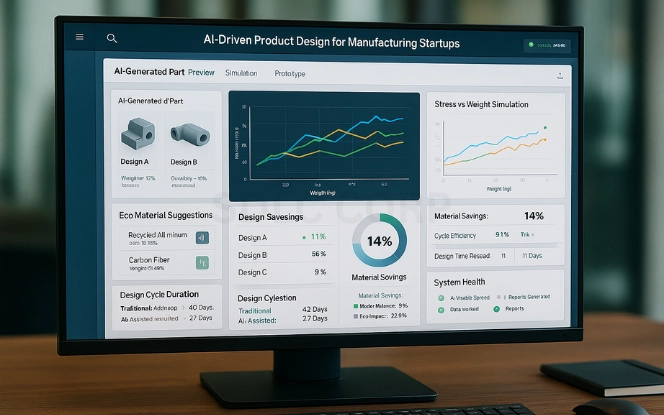

Innovation Through Product Design

Design is where many startups spend most of their energy. Generative AI product design makes this process faster and more effective.

Key applications include:

- Weight optimization: Create lighter components without reducing strength.

- Digital simulations: Test designs virtually before creating prototypes.

- Sustainability: Suggest alternative materials with lower environmental impact.

- Reduced waste: Minimize material use through AI-driven recommendations.

Product Design and Engineering Support:

In product development, generative models assist with design alternatives, material simulations, and technical documentation. Startups working on rapid prototyping often need engineers who understand both manufacturing logic and model behaviour. At this stage, teams may choose to hire generative AI developers to implement and fine-tune models that align with engineering requirements rather than generic outputs.

Startups can now explore hundreds of design variations in hours rather than weeks. This improves creativity while reducing trial-and-error, a major advantage for companies with small teams and budgets.

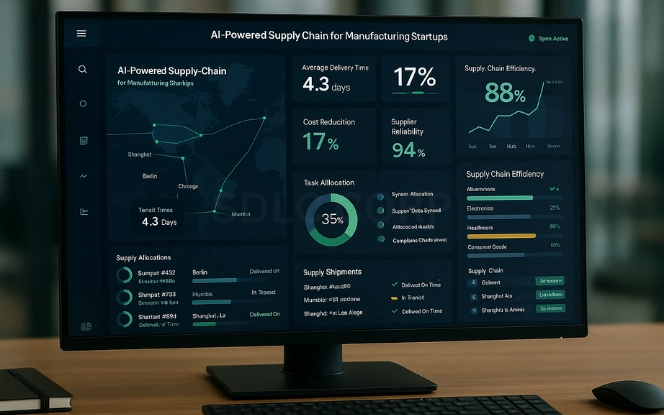

Supply Chain Optimization with AI

Supply chains often decide whether startups succeed or fail. Small disruptions can create delays that ripple across production. AI-powered supply chain optimization addresses these risks.

What AI offers in supply chains:

- Demand forecasting to avoid stockouts or overproduction.

- Real-time supplier risk assessment.

- Route optimization for faster, cheaper deliveries.

- Scenario simulation for alternate supplier strategies.

For example, if a supplier fails to deliver on time, AI recommends an alternative vendor or shipping route. Moreover, startups gain a live view of inventory, suppliers, and logistics, which helps them act before issues escalate.

Predictive Maintenance with Generative AI

Unplanned downtime can drain startup resources. Generative AI predictive maintenance lowers this risk by spotting issues before they turn into breakdowns.

Advantages for startups include:

- Early alerts when machines deviate from normal behavior.

- Longer equipment life through scheduled servicing.

- Fewer emergency repairs and lower costs.

- Reliable delivery timelines for customers.

A manufacturing startup might install sensors on machines to collect vibration and temperature data. When AI detects unusual patterns, it alerts managers. As a result, repairs happen before production stops. Over time, the AI learns patterns and improves predictions.

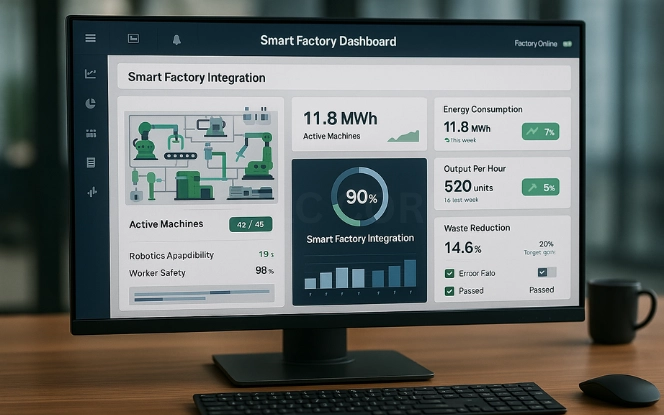

Building Smart Factories with AI Integration

Smart factories connect machines, systems, and people in real time. Smart factory AI integration gives startups this advantage without requiring large budgets.

Smart factory benefits include:

- Monitoring energy use and reducing waste.

- Automated production line adjustments.

- Robots adapting to new tasks with minimal programming.

- Worker safety checks through AI-enabled sensors.

For instance, AI may detect when a robotic arm is consuming excess energy and adjust its function. In addition, AI creates a unified view of the entire factory, enabling quick responses to production issues.

Case Studies: Generative AI in Action

Startup A: Product Innovation

- Used generative AI product design for automotive parts.

- Achieved 12% material reduction and stronger components.

Startup B: Supply Chain Agility

- Applied AI-powered supply chain optimization for medical devices.

- Identified alternate suppliers during a global disruption.

- Maintained output while competitors faced shortages.

Startup C: Predictive Maintenance

- An electronics startup adopted generative AI predictive maintenance.

- Downtime reduced by 30%, saving repair costs.

Startup D: Smart Factory Integration

- The furniture startup implemented smart factory AI integration.

- Automated inventory and material handling.

- Increased production speed by 20% and cut waste by 15%.

These examples highlight practical results, proving that generative AI in manufacturing startups is not only experimental but already delivering value.

Ethical and Regulatory Considerations

Manufacturing startups adopting AI must consider both ethics and compliance. Generative AI in manufacturing startups works with sensitive production and supply chain data, making security essential.

Points to address include:

- Data protection: Meeting rules such as GDPR and ISO standards.

- Transparency: Ensuring AI decisions are explainable and traceable.

- Bias: Training AI systems with diverse data to avoid unfair results.

- Compliance: Audits and validations to meet industry regulations.

Decision Support and Risk Assessment:

As startups scale, decisions around production planning, quality control, and supplier management become more complex. Generative AI can support scenario analysis and reporting, but these systems still require clear boundaries and evaluation. Some organisations work with a Generative AI consulting company to assess feasibility, identify suitable use cases, and ensure models are deployed responsibly within manufacturing environments.

By planning for these issues early, startups avoid costly setbacks. Moreover, strong compliance enhances credibility with investors and customers.

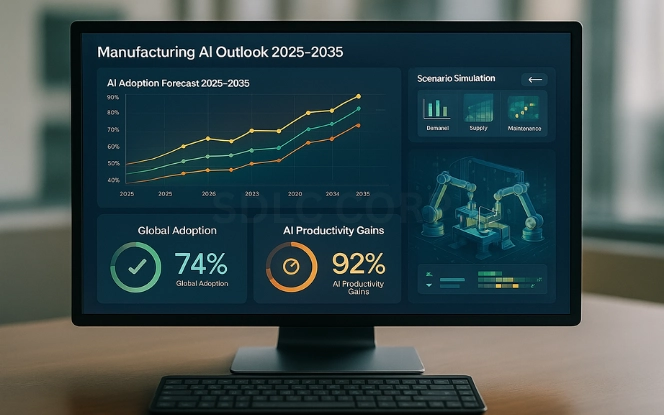

The Future of Generative AI in Manufacturing Startups

Generative AI will continue to grow in influence as startups expand their capabilities.

Future trends may include:

- Autonomous design cycles with minimal human intervention.

- Supply chains that adapt automatically to political and environmental risks.

- Predictive maintenance evolving into self-healing machines.

- Smart factories powered entirely by AI decision systems.

As computing power increases, AI will handle larger data sets and create more precise models. Startups that adopt early will gain significant competitive advantages in speed, cost efficiency, and adaptability.

Conclusion

Generative AI in manufacturing startups is already reshaping how products are designed, maintained, and delivered.

By applying AI-driven manufacturing innovation to product design, supply chain optimization, predictive maintenance, and smart factory AI integration, startups reduce costs and risks while improving quality.

Moreover, they position themselves as leaders in a competitive industry. For startups ready to move forward, the next step is clear: Contact us SDLC Corp to explore how AI can strengthen your manufacturing journey.

To take the next step, Hire AI Development Services with SDLC Corp and explore how tailored solutions can transform your organization.

Read Related Blogs:

FAQs

How Can Generative AI In Manufacturing Startups Improve Product Design?

Generative AI product design allows startups to input material, cost, and performance requirements. The system generates optimized designs that balance weight, durability, and sustainability. Startups save time by reducing physical prototypes and testing designs virtually. This improves efficiency, reduces waste, and supports innovative product development at lower costs.

What Is The Role Of AI-Driven Manufacturing Innovation For Startups?

AI-driven manufacturing innovation helps startups increase speed and efficiency by automating repetitive tasks, predicting outcomes, and analyzing data. It reduces production errors, improves quality, and accelerates decision-making. For startups with limited resources, AI enables them to compete with larger companies while maintaining agility and reducing operational costs.

How Does AI-Powered Supply Chain Optimization Support Startups?

AI-powered supply chain optimization helps startups predict demand, identify risks, and improve supplier reliability. By analyzing real-time logistics and supplier data, startups can avoid delays, minimize costs, and respond quickly to disruptions. In addition, AI creates more transparency across the supply chain, which strengthens relationships with partners and improves customer trust.

Why Is Generative AI Predictive Maintenance Important In Manufacturing?

Generative AI predictive maintenance allows startups to track machine performance and detect problems early. By analyzing sensor data such as vibration, heat, or pressure, AI predicts potential failures before they cause downtime. This reduces repair costs, increases equipment lifespan, and keeps production schedules on track, which is vital for resource-limited startups.

What Are The Benefits Of Smart Factory AI Integration For Startups?

Smart factory AI integration connects machines, sensors, and systems to improve efficiency and reduce waste. AI monitors operations in real time, automates adjustments, and improves worker safety through predictive monitoring. For startups, this means higher productivity, better energy management, and greater flexibility to adapt production lines when demand changes.