Odoo for Japan Manufacturing Industry

Enhancing production precision, improving material synchronization, and enabling real time operational intelligence across Japan’s manufacturing sector.

About

Japan’s manufacturing industry spans automotive, electronics, machinery, robotics, chemicals, and high-tech components, yet many factories still face delays due to siloed systems and manual reporting. These gaps affect quality consistency, production speed, and workflow planning. SDLC Corp delivers an Odoo integrated manufacturing ecosystem that connects production, procurement, inventory, and quality into one real time operational framework for smoother, reliable, and data-driven performance.

Industry

Manufacturing & Industrial Production

Services

Odoo ERP Setup, Production & Shop-Floor Management, Accounting & HR Integration

Business Type

Manufacturers, Fabrication Plants, Industrial Producers, Machinery & Automotive Component Makers

Build your idea

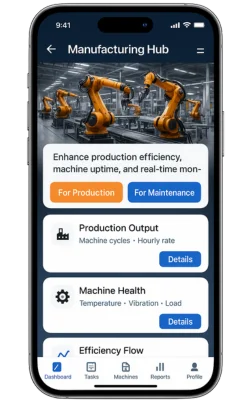

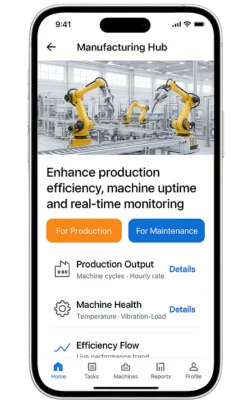

Precision & Real-Time Performance with Odoo for the Japan Manufacturing

The manufacturer struggled with slow decision making caused by delayed reporting, inconsistent material supply, and fragmented visibility across production lines. Teams were unable to spot issues early, which led to scheduling inefficiencies and reduced output stability. We deployed an integrated Odoo environment that centralized production operations, synchronized material usage, and delivered real time insights to every department involved in manufacturing.

Centralized manufacturing operations with an Odoo platform unifying production, planning, maintenance, accounting, and HR.

Automated workflows that optimize production sequences, replenishment cycles, and cost reporting.

Real-time visibility into machine performance, work-order status, material usage, and productivity levels.

Improved coordination between shop-floor operators, planning departments, finance teams, and quality units.

Reduced manual errors and enhanced cost control through automated processes and accurate reporting.

During our time working with manufacturers in Japan, what stood out most was the pride teams took in every detail of their work. Yet many told us they felt constrained by systems that didn’t match their discipline or pace. Our goal was to support that commitment by giving them tools that felt as reliable as their own processes. With a unified Odoo environment, teams gained clearer insight into their operations, fewer disruptions, and the freedom to focus on craftsmanship rather than system limitations. Seeing that shift on the shop floor confirmed how powerful the right technology can be when it respects the way people work.

Kishan Srivastava

CEO

Our Challenges

1

Limited Fleet Visibility

Factories lacked real-time insights into material availability, machine performance, production progress, or work-order movement.

2

Manual Trip Logs & Cost Reporting

Paper-based tracking caused delays, inconsistencies, and errors across production operations.

3

Reactive Maintenance

Unexpected equipment failures increased operational costs and caused avoidable production downtime.

4

Disconnected Financial & Operational Systems

No unified view of expenses, payroll, material costs, vendor billing, or production-related spending.

5

Compliance & Documentation Complexity

Certifications, safety checks, and regulatory documents were difficult to track across multiple facilities.

6

Lack of Operational Insights

Manufacturers struggled to analyze output patterns, efficiency trends, and production quality metrics.

Drive Your Manufacturing Plant Toward a Major Efficiency Milestone

Our Solutions

1

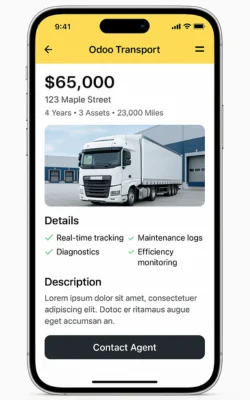

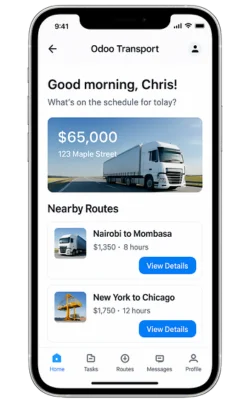

Fleet Management

Real-time tracking of production status, material levels, machine usage, and work-order performance.

2

Trip & Route Scheduling

Automated planning, optimized routing, and digital work-order logs to streamline production movement.

3

Predictive Maintenance

Automated alerts based on usage data and maintenance thresholds to prevent breakdowns.

4

Logistics & Dispatch Management

Enhanced coordination for material movement, plant-to-plant transfers, production cycles, and fulfillment.

5

Integrated Accounting & HR

Automated payroll, workforce tracking, expense management, and vendor billing within one system.

6

Compliance & Document Management

Digitized safety certificates, equipment logs, inspection reports, and regulatory records.

The Results

The Odoo powered environment improved production predictability, reduced material related interruptions, and strengthened cross team coordination. Real time insights helped supervisors act quickly, procurement aligned with actual demand, and production cycles became more consistent. Japanese manufacturers gained a stable, scalable digital foundation capable of supporting precision driven growth and future automation initiatives.

$9.5 Million

Annual savings

35%

Efficiency boost

4,500+

Live tracking metrics

Testimonials

Prabhakar Posam

On time delivery:

Reporting:

Communication:

Code Quality:

Availability:

Praful Tembhurne

On time delivery:

Reporting:

Communication:

Code Quality:

Availability:

On time delivery:

Reporting:

Communication:

Code Quality:

Availability:

I was impressed with the project development solution provided by SDLC Corp for my mobile app. Their cross-platform apps are available on both the iOS (apple app store) and Android app stores, and I highly recommend them as a mobile app development company.

Contact Us

Share a few details about your project, and we’ll get back to you soon.

Let's Talk About Your Project

- Free Consultation

- 24/7 Experts Support

- On-Time Delivery

- sales@sdlccorp.com

- +1(510-630-6507)