Odoo for Kenya Manufacturing Industry

Improving production visibility, strengthening material flow, and enabling real time operational accuracy across Kenya’s manufacturing sector.

About

Kenya’s manufacturing sector spans food processing, textiles, construction materials, chemicals, plastics, and consumer goods, yet many factories still rely on manual tracking and disconnected systems. These gaps create delays, reduce planning accuracy, and slow daily production. SDLC Corp delivers an Odoo enabled manufacturing ecosystem that unifies production, inventory, procurement, and quality into a single real time platform for smoother and more efficient operations.

Industry

Manufacturing & Industrial Production

Services

Odoo ERP Setup, Production & Shop-Floor Management, Accounting & HR Integration

Business Type

Manufacturers, Fabrication Plants, Industrial Producers, Machinery & Automotive Component Makers

Build your idea

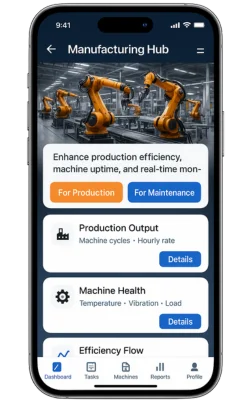

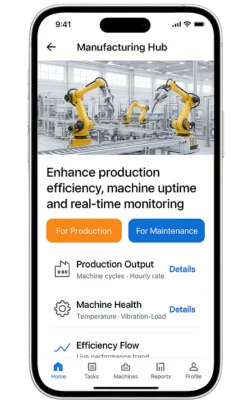

Precision & Real-Time Performance with Odoo for the Kenya Manufacturing

The manufacturer struggled with slow updates, inconsistent material supply, and fragmented visibility across production lines. Teams were unable to identify issues early because information arrived late or through scattered channels. We deployed an integrated Odoo ecosystem that centralized production operations, synchronized material consumption, and gave every department real time insight into workflow progress.

We improved operational stability further by automating work order sequencing, digitizing quality inspections, and enabling live tracking of raw materials and batch movement. Procurement teams benefited from forecasting tools, supplier timelines, and automated reorder alerts. Managers monitored cycle durations, equipment load, shift performance, and product quality through interactive dashboards. This created smoother workflows, faster decisions, and more predictable operational cycles.

In our work with manufacturing teams across Kenya, we saw how committed they were to improving output even when their systems limited visibility and coordination. Our aim was to give them a clearer way to manage each stage of production. By implementing a unified Odoo environment, we helped teams work with real time insights, reduced uncertainty in daily decisions, and improved communication across departments. With structured workflows and dependable data, Kenyan factories can now operate with greater stability and plan for long term growth with confidence.

Kishan Srivastava

CEO

Our Challenges

1

Limited Fleet Visibility

Factories lacked real-time insights into material availability, machine performance, production progress, or work-order movement.

2

Manual Trip Logs & Cost Reporting

Paper-based tracking caused delays, inconsistencies, and errors across production operations.

3

Reactive Maintenance

Unexpected equipment failures increased operational costs and caused avoidable production downtime.

4

Disconnected Financial & Operational Systems

No unified view of expenses, payroll, material costs, vendor billing, or production-related spending.

5

Compliance & Documentation Complexity

Certifications, safety checks, and regulatory documents were difficult to track across multiple facilities.

6

Lack of Operational Insights

Manufacturers struggled to analyze output patterns, efficiency trends, and production quality metrics.

Drive Your Manufacturing Plant Toward a Major Efficiency Milestone

Our Solutions

1

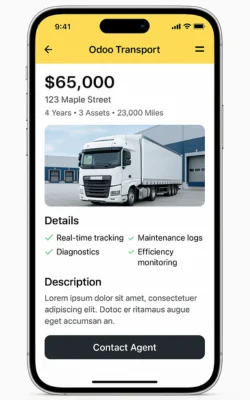

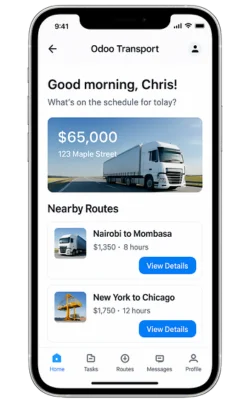

Fleet Management

Real-time tracking of production status, material levels, machine usage, and work-order performance.

2

Trip & Route Scheduling

Automated planning, optimized routing, and digital work-order logs to streamline production movement.

3

Predictive Maintenance

Automated alerts based on usage data and maintenance thresholds to prevent breakdowns.

4

Logistics & Dispatch Management

Enhanced coordination for material movement, plant-to-plant transfers, production cycles, and fulfillment.

5

Integrated Accounting & HR

Automated payroll, workforce tracking, expense management, and vendor billing within one system.

6

Compliance & Document Management

Digitized safety certificates, equipment logs, inspection reports, and regulatory records.

The Results

The Odoo powered system improved production reliability, reduced workflow interruptions, and strengthened coordination between teams. Real time insights helped supervisors reduce delays, procurement aligned with actual material usage, and production cycles became more predictable. Kenyan manufacturers now operate with improved clarity and a scalable digital structure designed for long term growth.

$9.5 Million

Annual savings

35%

Efficiency boost

4,500+

Live tracking metrics

Testimonials

Prabhakar Posam

On time delivery:

Reporting:

Communication:

Code Quality:

Availability:

Praful Tembhurne

On time delivery:

Reporting:

Communication:

Code Quality:

Availability:

On time delivery:

Reporting:

Communication:

Code Quality:

Availability:

I was impressed with the project development solution provided by SDLC Corp for my mobile app. Their cross-platform apps are available on both the iOS (apple app store) and Android app stores, and I highly recommend them as a mobile app development company.

Contact Us

Share a few details about your project, and we’ll get back to you soon.

Let's Talk About Your Project

- Free Consultation

- 24/7 Experts Support

- On-Time Delivery

- sales@sdlccorp.com

- +1(510-630-6507)