Introduction

Odoo ERP is a fully integrated, open-source enterprise resource planning solution designed to unify various business processes into one platform. For manufacturers, Odoo offers specialized modules that handle production planning, inventory tracking, procurement, and supply chain management.

By leveraging Odoo Manufacturing Software, businesses gain access to intelligent automation, real-time data, and streamlined workflows enabling them to focus more on growth and innovation.

The Challenges Faced by Manufacturing Units

- Inaccurate inventory tracking

- Overstocking or understocking materials

- Complex bill of materials (BOM) management

- Lack of real-time visibility

- Manual data entry and siloed systems

- Poor coordination between departments

- Low production efficiency and bottlenecks

Key Features of Odoo ERP Inventory Management

Odoo ERP inventory management is one of the most powerful and flexible tools in the ERP market. Here’s how it benefits manufacturers:

1. Real-Time Stock Visibility

Odoo ERP provides live tracking of inventory levels across all your warehouses and locations. This ensures informed decision-making and eliminates the risk of stockouts or overstocking.

2. Automated Reordering Rules

Manufacturers can define minimum and maximum stock thresholds, allowing Odoo to automatically trigger purchase orders when stock falls below the set level, ensuring continuous operations.

3. Advanced Barcode Scanning

With Odoo’s barcode integration, warehouse staff can perform actions like inventory updates, order fulfillment, and internal transfers faster and more accurately, reducing manual errors.

4. Serial Number and Lot Tracking

Odoo allows detailed tracking of each product using serial or lot numbers, enabling complete traceability for warranty claims, recalls, or quality audits.

5. FIFO, LIFO, and Average Costing

Odoo supports multiple costing methods such as First In First Out (FIFO), Last In First Out (LIFO), and average costing to align with your accounting and compliance needs.

How Odoo ERP Streamlines Production Operations?

The Odoo Manufacturing module is designed to simplify all production-related tasks. From scheduling work orders to managing multi-level BOMs, it offers end-to-end control.

a. Master Production Schedule (MPS)

The MPS in Odoo enables manufacturers to plan production activities based on real-time demand, inventory availability, and resource capacity. It helps balance supply with market demand, preventing overproduction or stockouts.

b. Bill of Materials (BOM)

Odoo allows the creation of single or multi-level BOMs linked to specific products and processes. This ensures detailed material tracking and cost estimation throughout the production lifecycle.

c. Work Orders and Routing

Define step-by-step routing for each product and automatically generate work orders based on routing stages. This improves process flow and ensures each production unit is accountable for specific tasks.

d. Quality Control

Incorporate quality checkpoints at every stage of production—initial input, in-process, and final output. This ensures defect-free products and enhances customer satisfaction by maintaining consistent standards.

e. Maintenance Management

Leverage preventive and predictive maintenance tools to schedule timely equipment servicing. This minimizes unplanned downtime and increases the lifespan of machines on the shop floor.

f. Time Tracking and Reporting

Track the actual time taken for each work order and compare it with estimates. Use detailed reports to identify bottlenecks and improve workforce efficiency and job costing accuracy.

These features allow Odoo ERP to streamline manufacturing from raw material procurement to final delivery.

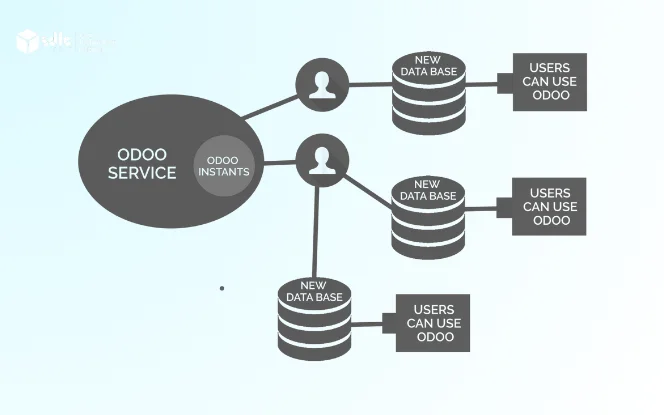

Odoo’s Modular Structure and Integration Benefits

One of the strongest aspects of Odoo ERP implementation is its modular architecture. You can start with essential modules like Inventory, Manufacturing, and Purchase, and gradually expand with CRM, Sales, Accounting, and HR.

Benefits of Modular Odoo Solutions:

- Scalable growth model

- Reduced initial investment

- Easy training and onboarding

- No unnecessary complexity

Because all modules are integrated natively, Odoo’s integration ensures seamless data flow across departments eliminating silos and improving decision-making.

Real-Time Tracking and Forecasting in Odoo ERP

Real-time tracking is a game-changer in production and inventory management. Odoo ERP streamlines operations by providing:

- Live dashboards for KPIs

- Automatic demand forecasting

- Real-time resource allocation

- Live inventory tracking across channels

These tools not only help in optimizing inventory but also enhance the agility of production processes.

Use Case: Odoo ERP Implementation in a Mid-Sized Manufacturing Unit

Let’s consider a mid-sized electronics manufacturer struggling with production delays and stockouts.

a. Problems Faced:

- Manual stock entry

- Frequent raw material shortages

- Lack of synchronization between departments

b. Odoo ERP Implementation:

- Used Odoo’s Manufacturing, Inventory, and Purchase modules

- Set up automated replenishment rules

- Enabled barcode scanning for warehouse

- Integrated real-time dashboards for tracking production

c. Outcome:

- 30% reduction in production delays

- 45% increase in inventory accuracy

- Streamlined communication across departments

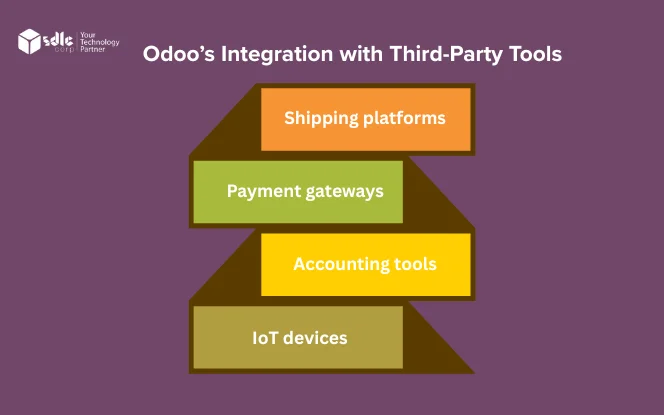

Odoo’s Integration with Third-Party Tools

While Odoo’s integration within its ecosystem is seamless, it also supports third-party tool integrations for enhanced functionality.

Popular integrations include:

- Shipping platforms like FedEx, UPS, DHL

- Payment gateways such as Stripe, PayPal

- Accounting tools like QuickBooks or external APIs

- IoT devices for smart manufacturing insights

This openness makes Odoo ideal for manufacturers aiming for a connected smart factory environment.

Best Practices for Odoo ERP Implementation

To ensure success with Odoo ERP implementation, manufacturers should follow these best practices:

a. Define Clear Objectives

Start by identifying your core business challenges and setting measurable KPIs. This ensures the Odoo ERP implementation aligns with real business goals and drives measurable results.

b. Data Migration and Testing

Cleanse and validate all legacy data before migrating it into the new system. Thoroughly test data workflows and module functionality to avoid disruptions post-deployment.

c. Train Your Team

Conduct role-based training sessions for key departments to ensure smooth adoption. A well-trained team can leverage Odoo’s modular tools effectively and maximize ROI.

d. Start Small, Scale Smart

Implement core modules first such as Inventory, Manufacturing, or Sales and expand gradually. This phased approach minimizes risk and allows for smoother organizational adaptation.

Conclusion

In a manufacturing environment where precision, efficiency, and agility are essential, Odoo ERP streamlines production and inventory management like no other system. By integrating manufacturing workflows, inventory tracking, procurement, and analytics into a single platform, Odoo ERP helps businesses scale efficiently and make smarter decisions.

Whether you’re a growing SME or an enterprise manufacturer, adopting Odoo solutions ensures that your operations remain future-ready, agile, and competitive. Its modular architecture, real-time capabilities, and deep integration features make Odoo ERP for manufacturers not just a tool but a transformational asset.

FAQS

How Does Odoo ERP Streamline Inventory Management for Manufacturing Businesses?

Odoo ERP streamlines inventory management by offering real-time tracking of raw materials, finished goods, and in-transit stock. Through Odoo ERP Inventory, manufacturers can automate replenishment, manage multiple warehouses, and eliminate stockouts using smart forecasting tools all in a centralized dashboard.

What Production Planning Features Does Odoo Manufacturing Software Provide?

Odoo Manufacturing Software provides powerful production planning tools such as Master Production Schedule (MPS), automated work order routing, and multi-level Bill of Materials (BoM). These features help manufacturers align production cycles with inventory availability and customer demand efficiently.

How Can Odoo ERP Help Reduce Production Delays and Bottlenecks?

Odoo ERP reduces delays and bottlenecks by automating task scheduling, resource allocation, and work center monitoring. The real-time data and customizable dashboards in Odoo Manufacturing Module enable managers to identify and resolve issues before they impact delivery timelines.

What Are the Benefits of Integrating Inventory and Production in Odoo’s Modular ERP System?

Odoo’s modular ERP integration allows seamless data flow between inventory and production. This results in synchronized updates across procurement, stock levels, and manufacturing orders, which minimizes manual errors and increases operational transparency for better decision-making.

Why Is Odoo ERP Ideal for Manufacturers Looking to Scale Operations?

Odoo ERP is ideal for scaling manufacturers because of its flexible, modular structure. Businesses can start with core modules like inventory and production, then scale by integrating accounting, CRM, quality control, and more. This supports sustainable growth with minimal disruption.

Can Odoo ERP Improve Forecasting and Demand Planning in Manufacturing?

Yes, Odoo ERP enhances forecasting and demand planning using real-time inventory analytics and historical sales data. The system can generate demand forecasts, automate procurement suggestions, and optimize production scheduling, reducing waste and improving inventory turnover.

How Does Odoo ERP Support Lean Manufacturing Practices?

Odoo ERP supports lean manufacturing by minimizing excess inventory, reducing production waste, and optimizing workflows. Features like Just-in-Time inventory management, Kanban scheduling, and automated quality checks contribute to leaner, more efficient manufacturing processes.