Introduction

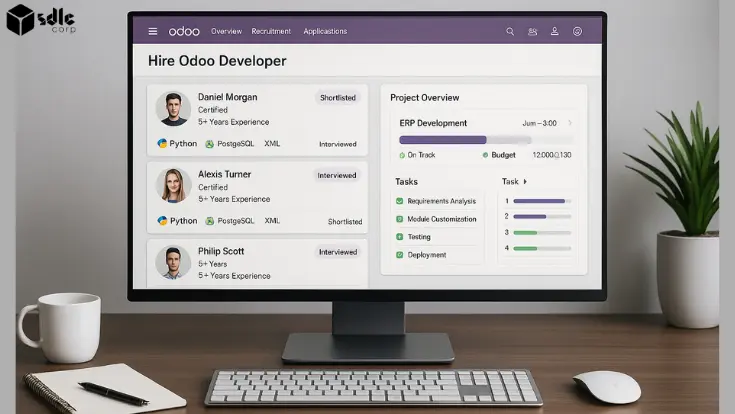

In the fast-evolving manufacturing landscape, businesses increasingly shift from mass production models to more dynamic, custom-driven project-based manufacturing. This shift is especially prominent in sectors like aerospace, construction, industrial machinery, and engineer-to-order (ETO) operations, where each job is unique, deadline-oriented, and resource-intensive. To effectively manage this complexity, companies require a comprehensive and agile ERP solution and Odoo delivers precisely that.

Odoo ERP offers an integrated suite of applications designed to streamline every aspect of project-based manufacturing, from resource planning and bill of materials to task tracking and production scheduling. Let’s explore how Odoo’s project manufacturing module empowers businesses to execute custom projects efficiently and profitably.

1. Centralizing Manufacturing Projects with Odoo ERP

- Project management

- Inventory tracking

- Production planning

- Accounting integration

- Human resource management

Key Capabilities:

- Create and manage project manufacturing orders linked directly to sales or service contracts.

- Integrate every BoM variation with project-specific requirements using Odoo BoM for projects.

- Utilize the Odoo project manufacturing module to associate timelines, deliverables, and stakeholders with each production cycle.

2. Structuring Manufacturing Orders by Project

Odoo allows you to configure manufacturing orders to align with each individual project. This is especially useful for engineer-to-order companies, where production begins only after the design is finalized and customer approval is received.

Features That Enhance Manufacturing Orders in Odoo:

- Assign each MO to a corresponding Odoo project.

- Break down MOs into smaller Odoo manufacturing work orders for each task or department.

- Link every work order to deadlines, dependencies, and human resources via the Odoo MRP project interface.

This flexibility ensures that complex, custom-built items are tracked and delivered with precision.

3. Odoo MRP Scheduling: Real-Time Production Timeline

Managing timelines is critical in project-centric manufacturing. The Odoo MRP scheduling system enables manufacturers to define lead times, allocate buffers, and adjust schedules dynamically based on task progress.

Benefits of Odoo MRP Scheduling:

- Gantt chart views of planned vs actual progress

- Automated alerts for delays or material shortages

- Forecasted production timelines based on historical data

Whether it’s a one-off prototype or a large infrastructure component, Odoo’s scheduler helps ensure on-time delivery.

4. Managing Project-Based Bill of Materials (BoM)

In project-based environments, BoMs are rarely static. Clients may request changes mid-way, components may need upgrades, or design modifications may arise. Odoo accommodates this through customizable Odoo BoM for projects.

Why Odoo BoM Stands Out:

- Variant BoMs for different project scopes

- Version control to track BoM updates over time

- Link BoMs to project tasks and production phases

This allows manufacturers to quickly adapt and reflect changes across procurement, inventory, and assembly without disrupting workflows.

5. Efficient Resource Allocation in Manufacturing Projects

Mismanagement of personnel, machinery, or materials can derail a project timeline. Odoo’s resource allocation manufacturing tools give project managers visibility into resource availability and workload balance.

Odoo’s Resource Allocation Tools Offer:

- Skill-based task assignments

- Equipment scheduling

- Material consumption forecasts

- Shift planning and time tracking

This capability supports just-in-time production by ensuring the right resources are available when and where they are needed.

6. Project Task Tracking for Execution & Accountability

Odoo’s project task tracking functionality helps teams stay on target throughout the project lifecycle. Tasks can be assigned to users or departments, tracked through Kanban boards, and linked directly to work orders.

Highlights of Project Task Tracking in Odoo:

- Real-time task status updates

- Custom stages like “In Design,” “Under Review,” “In Assembly”

- Time spent and deadlines logged against each task

This feature improves communication across departments and offers managers a bird’s-eye view of progress and delays.

7. Integrating Project Accounting with Manufacturing

Understanding the financial performance of each manufacturing project is key to profitability. Odoo seamlessly integrates project accounting with production workflows to track expenses, budget consumption, and ROI.

Key Financial Features:

- Record costs at every project stage

- Monitor budgets against real-time expenditure

- Generate profit/loss reports for each Odoo manufacturing ERP project

With project accounting Odoo, manufacturers gain actionable insights into where projects are succeeding or draining resources.

8. Streamlining Engineer-to-Order (ETO) with Odoo

ETO manufacturers often deal with complex requirements: CAD designs, supplier coordination, specialized certifications, and customer-specific changes. Odoo ERP for engineer-to-order production enables you to:

- Convert customer specifications into manufacturing tasks

- Integrate engineering documents within the project

- Monitor long lead-time components

The Odoo MRP project module links engineering tasks to manufacturing orders, streamlining communication between design and production teams.

9. Real-Time Reporting and Dashboards

Odoo offers real-time dashboards that provide operational and financial metrics at a glance.

Reporting Insights Include:

1. Work-in-progress value

Odoo tracks the current value of all unfinished manufacturing tasks, helping managers understand how much capital is tied up in production. This enables better cash flow planning and project prioritization. Real-time updates ensure accurate valuation at every stage of the workflow.

2. Order fulfillment rate

The dashboard shows the percentage of customer orders completed on time, offering a clear view of delivery performance. High fulfillment rates indicate efficient processes, while delays can trigger early intervention. This metric is essential for maintaining customer satisfaction.

3. Labor cost per task

Odoo calculates the cost of labor consumed per production task based on logged hours and employee rates. This allows managers to assess productivity and cost-efficiency across departments. It also helps in budgeting and quoting future projects more accurately.

4. Inventory turnover per project

This metric reflects how efficiently inventory is used within each project, showing how often stock is replaced over time. High turnover indicates effective stock management, reducing holding costs and waste. Odoo enables filtering this data by project for precise evaluation.

10. Quality Control & Compliance Tracking

Custom manufacturing projects often need strict quality control. Odoo supports this through embedded QC checkpoints within the Odoo manufacturing work orders.

a. Define tests at each stage of production

Odoo allows users to configure quality checkpoints throughout the manufacturing process. These can be set for raw materials, in-process assemblies, or final products. This ensures quality is built into every stage, not just at the end.

b. Record test results and non-conformities

With Odoo, you can log inspection results, capture deviations, and flag non-conforming items in real time. This traceability helps identify root causes quickly and supports corrective actions. Detailed records also support audit readiness and compliance.

c. Link QC checks to specific Odoo BoMs and customer specs

Odoo enables you to tie quality control criteria directly to the Bill of Materials and customer-defined specifications. This ensures each manufactured item is validated against exact standards. It reduces the risk of rework, rejection, and contractual penalties.

11. Inventory and Procurement Management

Project-specific production needs demand accurate stock forecasting. Odoo’s inventory module works hand-in-hand with the project manufacturing module to manage:

a. Component reservation per project

Odoo allows you to reserve specific inventory items for individual projects, preventing stock from being unintentionally allocated elsewhere. This ensures that critical components are always available when needed for each job. It minimizes production delays due to material shortages. This project-level control helps in maintaining operational discipline and clarity.

b. Procurement based on project timelines

With Odoo, procurement activities can be triggered according to each project’s specific schedule and milestones. The system aligns purchase orders with production deadlines to avoid early or late deliveries. This leads to better cash flow management and storage optimization. Just-in-time procurement becomes easier to implement and monitor.

c. Supplier order integration

Odoo seamlessly integrates supplier orders with ongoing manufacturing projects, providing full traceability from procurement to production. Each supplier order is linked to the corresponding project, ensuring accurate delivery tracking and cost allocation. Notifications and status updates are automated, reducing manual follow-ups. This integration improves supplier collaboration and project execution.

Conclusion

Project-based manufacturing demands more than just traditional ERP it requires an adaptive, real-time solution that understands the unique needs of custom production environments. Odoo delivers on all fronts. by combining Odoo MRP scheduling, Odoo BoM for projects, project accounting Odoo, and integrated work orders, businesses can improve delivery timelines, control costs, and ensure quality compliance.For manufacturers operating in the engineer-to-order space or dealing with complex production workflows, Odoo project manufacturing offers the tools to plan, execute, and scale effectively.

With its robust capabilities and modular design, Odoo manufacturing ERP is not just a software it’s your strategic partner in project-based manufacturing excellence.

FAQ's

How Are Work Orders Managed For Different Projects?

Each project can generate its own set of manufacturing work orders in Odoo, which can be tracked and managed independently in the MRP module.

Does Odoo Allow Linking Sales Orders To Manufacturing Projects?

Yes, Odoo enables seamless linking between sales orders and corresponding project-based manufacturing orders to ensure production meets specific client requirements.

Can Odoo Handle Custom Product Configurations Per Project?

Odoo’s product variants and engineering change order features help in managing customized configurations for each manufacturing project.

How Is Resource Allocation Handled In Odoo Project Manufacturing?

Odoo allows you to allocate machines, labor, and raw materials specifically for a project, using schedules and Gantt charts to manage utilization.

How Does Odoo Help With Manufacturing Order Scheduling?

Odoo MRP scheduling tools ensure that manufacturing orders are properly sequenced and resourced according to project timelines.

How Is Inventory Managed In Project-Based Manufacturing?

Inventory in Odoo is reserved per project, and procurement activities are aligned with each project’s schedule and material requirements.