Introduction

Odoo is a comprehensive suite of business applications designed to streamline manufacturing and production operations for businesses of all sizes. With its intuitive interface and powerful modular structure, Odoo enables you to manage everything from raw materials to finished goods all within a single, integrated platform. Whether it’s tracking inventory, managing work orders, or optimizing production schedules, Odoo offers scalable solutions tailored to the unique needs of the manufacturing sector.

Partnering with an experienced Odoo development company ensures that your platform is customized and implemented to meet your specific business goals, minimizing manual errors and maximizing productivity.

Step - by - Step Guide : Using Odoo for Manufacturing and Production

Implementing an ERP for manufacturing can seem complex, but with Odoo 18, the process becomes intuitive and streamlined. This step-by-step guide walks you through the actual workflow inside the Odoo Manufacturing module, from creating a Manufacturing Order to marking it as complete. Whether you’re new to ERP systems or migrating from legacy tools, this breakdown ensures you understand each step clearly and can begin optimizing your production pipeline immediately.

Follow these instructions to get started with digital manufacturing using Odoo’s smart features and real-time tools.

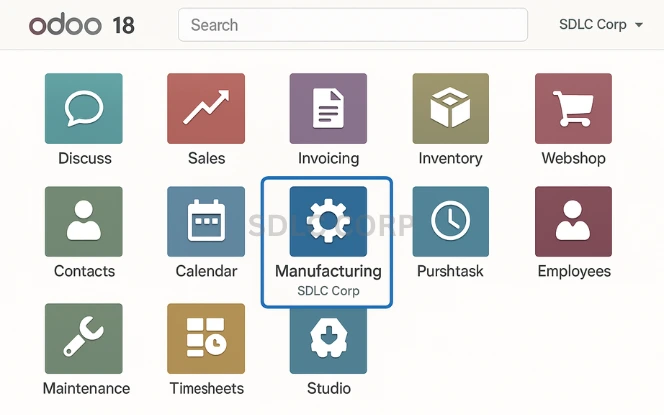

1. Access the Manufacturing Module

To begin, open your Odoo dashboard and locate the Manufacturing module.

- Go to the main dashboard

- Click on Manufacturing

- This is your control panel for all production operations

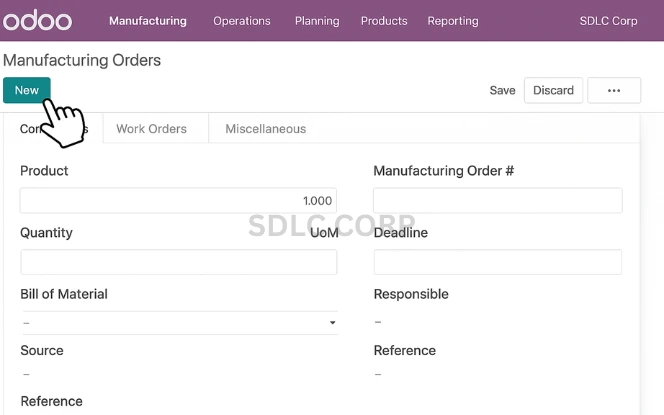

2. Create a New Manufacturing Order

Next, you’ll create a new Manufacturing Order (MO).

- Inside the Manufacturing module, click on New

- Select the product you want to manufacture

- The MO form will open for editing

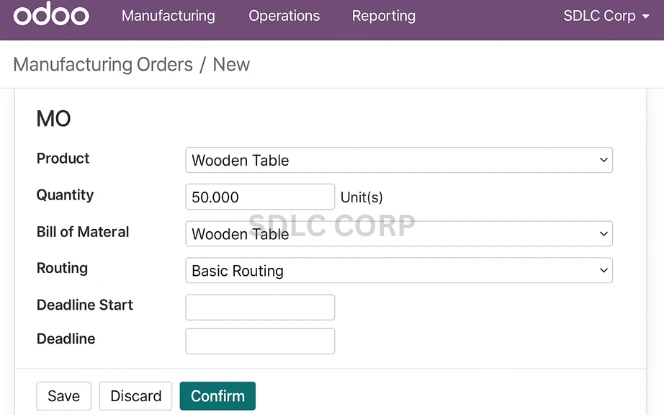

3. Enter Production Details and Confirm the MO

Fill in all the necessary fields in the MO form:

- Product to manufacture

- Quantity to produce

- Bill of Materials (BoM) and Routing (if required)

- Scheduled date for production

Once everything is complete:

- Click Confirm to finalize and move MO to Confirmed state

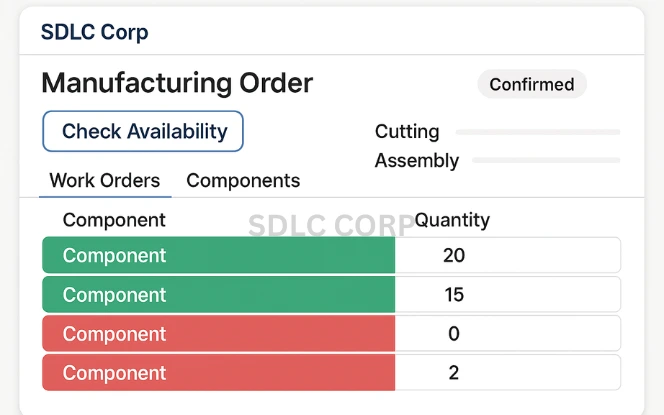

4. Check Component Availability and Plan Work Orders

Before beginning production:

Click Check Availability to ensure all raw materials are in stock

If any materials are missing, Odoo will prompt you to replenish or transfer

If Routing is enabled:

Odoo auto-generates Work Orders for each production step

Click the Work Orders smart button to review the generated work orders

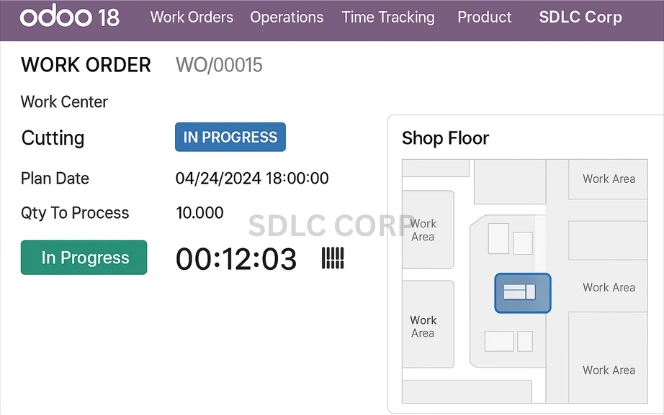

5. Start the Production Process

Once the MO is confirmed and materials are available:

- Navigate to the MO or Work Order

- Click Start or Mark as Started

- Use the Shop Floor app or barcode scanner to track real-time progress

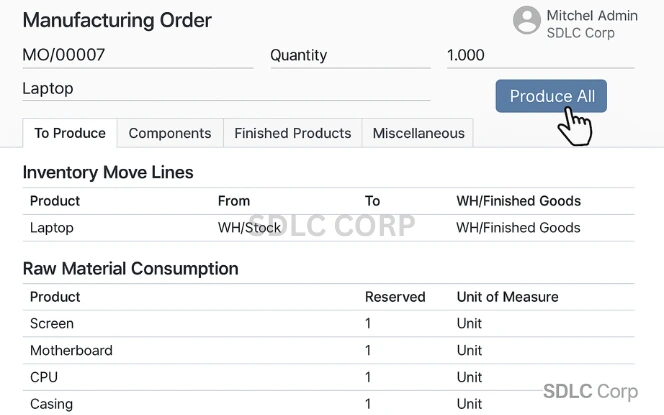

6. Record Production and Click “Produce All”

As production proceeds or finishes:

- Complete all associated Work Orders (if routing is used)

- Click Produce All on the MO to register material consumption and output

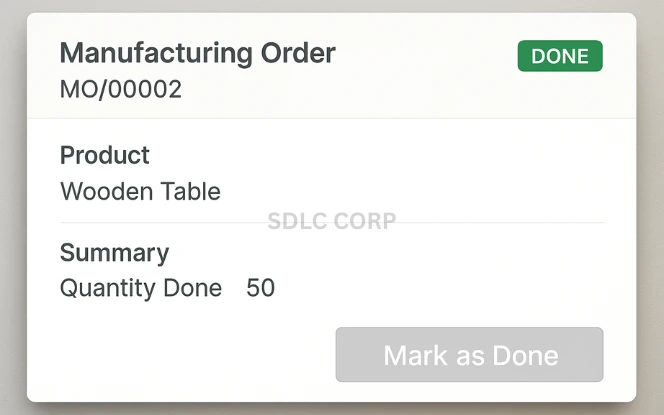

7. Mark the MO as Done

Once all production steps are complete:

- Click Mark as Done on the Manufacturing Order

- This action updates stock with finished goods and closes the MO

Benefits of Using Odoo for Manufacturing

Implementing Odoo can enhance your manufacturing operation by:

Streamlining production planning and execution

Providing real-time inventory and material tracking

Automating quality control and work order assignments

Reducing errors through data integration and traceability

By working with an Odoo development consultancy, you ensure your implementation is aligned with industry best practices, from initial setup to ongoing support.

Conclusion

Odoo 18 is a powerful ERP solution for modern manufacturing. By following a structured implementation plan and working with a trusted development partner like SDLC CORP, you can fully leverage Odoo’s capabilities to drive operational excellence.

Ready to take the next step? Contact SDLC CORP for a tailored Odoo manufacturing demo today.

How SDLC CORP Can Help with Odoo Development Services ?

As a top-tier Odoo development agency, SDLC CORP delivers full-cycle Odoo ERP development services designed to optimize business processes. Their team of skilled Odoo developers and consultants brings expertise across:

Custom module development for manufacturing, inventory, HR, CRM, and finance

Strategic ERP consulting to ensure process alignment and best practices

Ongoing platform support and technical upgrades

Seamless integrations with third-party tools and systems

With SDLC CORP’s Odoo customization services, manufacturers can enhance system flexibility and scale operations efficiently. From configuring shop floor control and subcontracting workflows to creating powerful dashboards, SDLC ensures that your Odoo ERP is tailored to meet real-world demands.

FAQ's

What is Odoo Manufacturing and how does it benefit my production process?

Odoo Manufacturing is a module within the Odoo ERP system designed to manage production workflows, work orders, material requirements, and inventory. It helps streamline operations, reduce manual errors, and improve real-time visibility across the entire production cycle.

How do I create a Manufacturing Order (MO) in Odoo?

To create an MO, go to the Manufacturing module, click New, select the product, enter the quantity, choose the Bill of Materials (BoM), and confirm the order. This starts the production process and can automatically generate work orders if routing is set.

Can I check raw material availability before starting production in Odoo?

Yes. Odoo lets you click Check Availability within the MO to ensure all required components are in stock. If not, it prompts you to reorder or transfer stock, ensuring smooth production flow without delays.

What is the role of Bill of Materials (BoM) in Odoo?

A BoM defines the components needed to manufacture a product. Odoo uses the BoM to automatically calculate material requirements and generate work orders, making the production process accurate and efficient.

Why choose SDLC CORP for Odoo Manufacturing & Production?

SDLC CORP is a one-stop solution for manufacturers adopting Odoo because we combine manufacturing domain depth + Odoo engineering strength in a single delivery team.

What we’ve done:

Delivered lots of successful Odoo manufacturing implementations across discrete, process, batch, and hybrid production.

Worked with startups, mid-size manufacturers, and large enterprises, adapting Odoo to real factory scale.

Supported multi-plant and multi-warehouse operations where production, inventory, and costing must stay in sync.

How we implement (process-first):

We start with your shop-floor reality, not generic ERP templates.

Blueprint your production end-to-end:

BOM structures (multi-level, phantom, alternates)

Routings & work centers

Capacity constraints & scheduling logic

WIP movement & shop-floor controls

Quality gates, NCR/CAPA, scrap & rework

True product costing & variance control

Then we configure Odoo to match that flow so it runs daily operations smoothly.

Result for you:

Odoo that fits your factory from day one.

Better planning accuracy, traceability, QC control, and cost visibility.

A system built to improve production performance, not just record transactions.

Do you provide a dedicated Odoo manufacturing team and on-site support?

Yes — SDLC CORP delivers manufacturing projects with a dedicated, factory-focused Odoo pod and optional on-site support, so execution is tight and adoption is fast.

Dedicated team includes:

Odoo Manufacturing Solution Architect

Functional Manufacturing Consultant

Technical Lead + Custom Dev Team

Integration Engineer (PLM/MES/IoT/Barcode/RFID)

QA + UAT Support

Project Manager

On-site support (when required):

Plant workshops for accurate process capture.

Go-live support to stabilize production without disruption.

Supervisor/operator training in real scenarios.

Hypercare in the first weeks to fine-tune MRP, work orders, and reporting.

Why this matters in factories:

Manufacturing success depends on small realities: machine bottlenecks, changeovers, WIP handling, inspection stages, and real routing decisions.

On-site + dedicated ownership ensures Odoo reflects these realities, not assumptions.

Bottom line:

You don’t get a rotating vendor pool. You get one team accountable for outcomes, end-to-end.

Can SDLC CORP handle complex manufacturing setups in Odoo?

Absolutely. Complex manufacturing is where SDLC CORP stands out as a true one-stop Odoo partner.

We set up Odoo for advanced production models like:

Engineer-to-Order (ETO), Make-to-Order (MTO), Make-to-Stock (MTS)

Multi-level / alternate BOMs, by-products & co-products

Batch + serial traceability across plants and warehouses

Subcontracting & vendor-managed production steps

Rework loops, scrap accounting, and NCR/CAPA workflows

Capacity-based planning with realistic work-center constraints

We also integrate the full manufacturing ecosystem:

PLM/CAD → engineering BOM sync & change control

MES/SCADA → shop-floor execution alignment

Barcode/RFID → real-time material & WIP traceability

IoT/machine data → condition-based maintenance triggers

Accounting → true standard vs actual costing & profitability

What this creates:

A digital thread from engineering → production → quality → maintenance → delivery.

KPIs manufacturers care about (OEE, yield, OTIF, scrap %, lead time, unit cost).

Odoo that scales as production grows, without re-platforming.